Halliburton provides operators with high-efficiency fixed cutter, roller cone, coring and hole enlargement tools for any drilling environment.

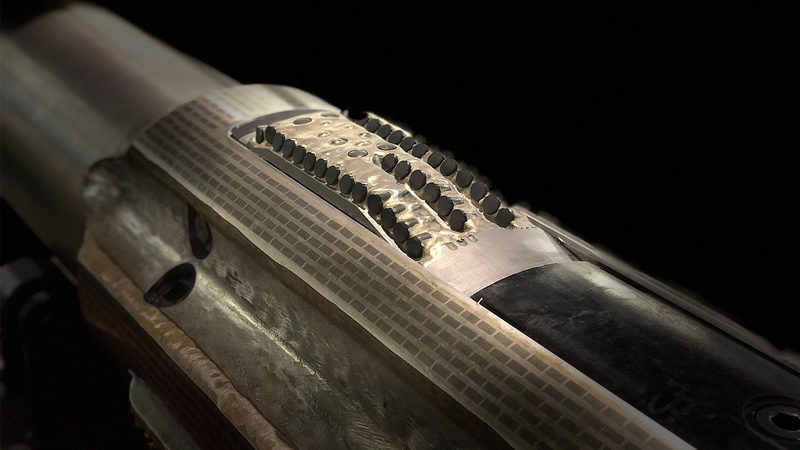

Talk to an expertWith different applications around the world, there is not a standard solution for every drilling environment, and our unique Design at the Customer Interface (DatCI™) process takes that into account. Rather than centralizing design for drill bits, Halliburton has highly trained Application Design Evaluation (ADE™) specialists in locations around the globe. This enables us to work directly with customers to design application-specific solutions. ADEs use the industry’s most powerful software to design drill bits and tools for our customers.

View HedronHedron drill bits are the next generation of fixed cutter bits. We’ve designed them to drill farther and faster than any previous bit generation.

Next-generation customized drill bits

02:17

TEXAS

Minimized run hours and eliminated costs associated with additional trips reduces overall costs for the operator.

READ CASE STUDYCOLOMBIA

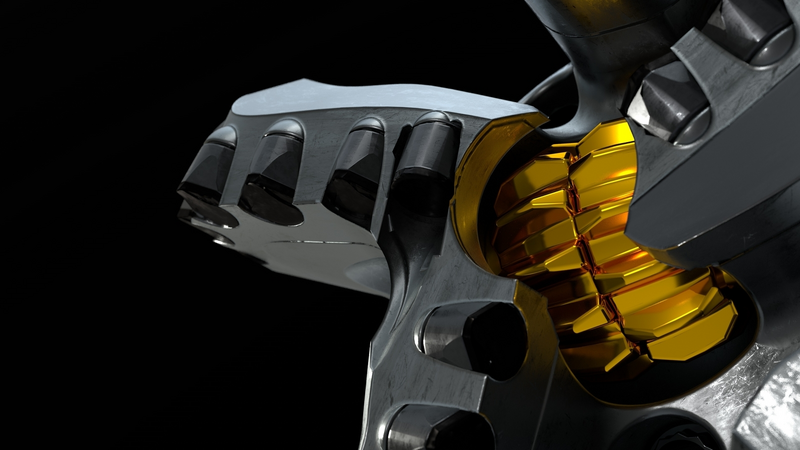

Discover how Juggernaut® cutters and Cerebro® in-bit sensing helps reduce drilling time for Parex Resources Colombia.

READ CASE STUDY

Halliburton delivers high-efficiency fixed cutter drill bit solutions that are customized for every application.

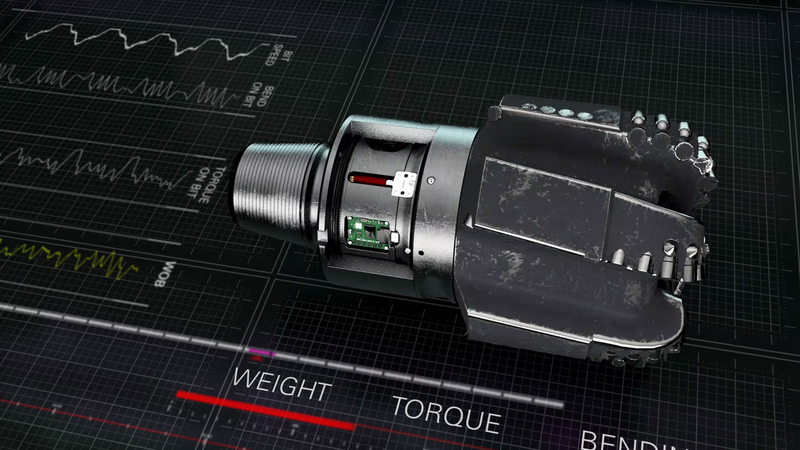

In-bit sensors give customers a better understanding of the downhole environment, reducing uncertainty and improving efficiency.

Halliburton roller cone drill bits are designed to meet your specific application needs.

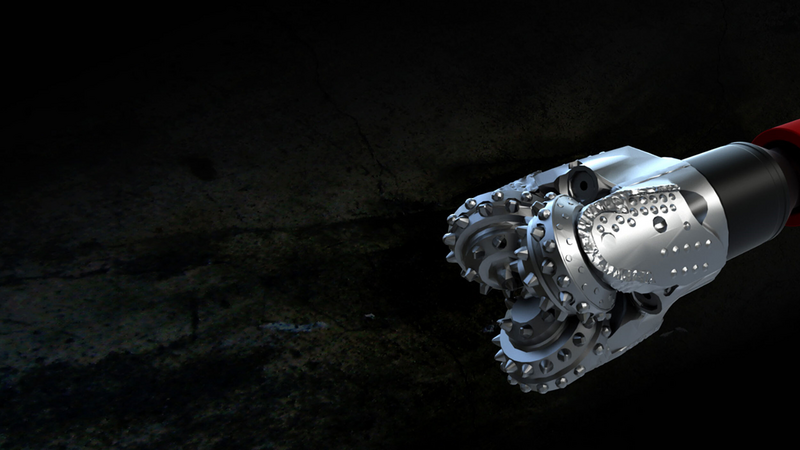

Hybrid drill bits combine the best of fixed cutter and roller cone technologies to increase control, durability, and ROP.

Coring systems that maximize recovery of high-quality core samples in the most extreme environments.

On-demand activation/deactivation systems where tool reliability, durability, and hole quality of the enlarged hole is important.