SentinelCem™ Pro cement system helps address challenges in complex reservoir

Download PDFMature Fields

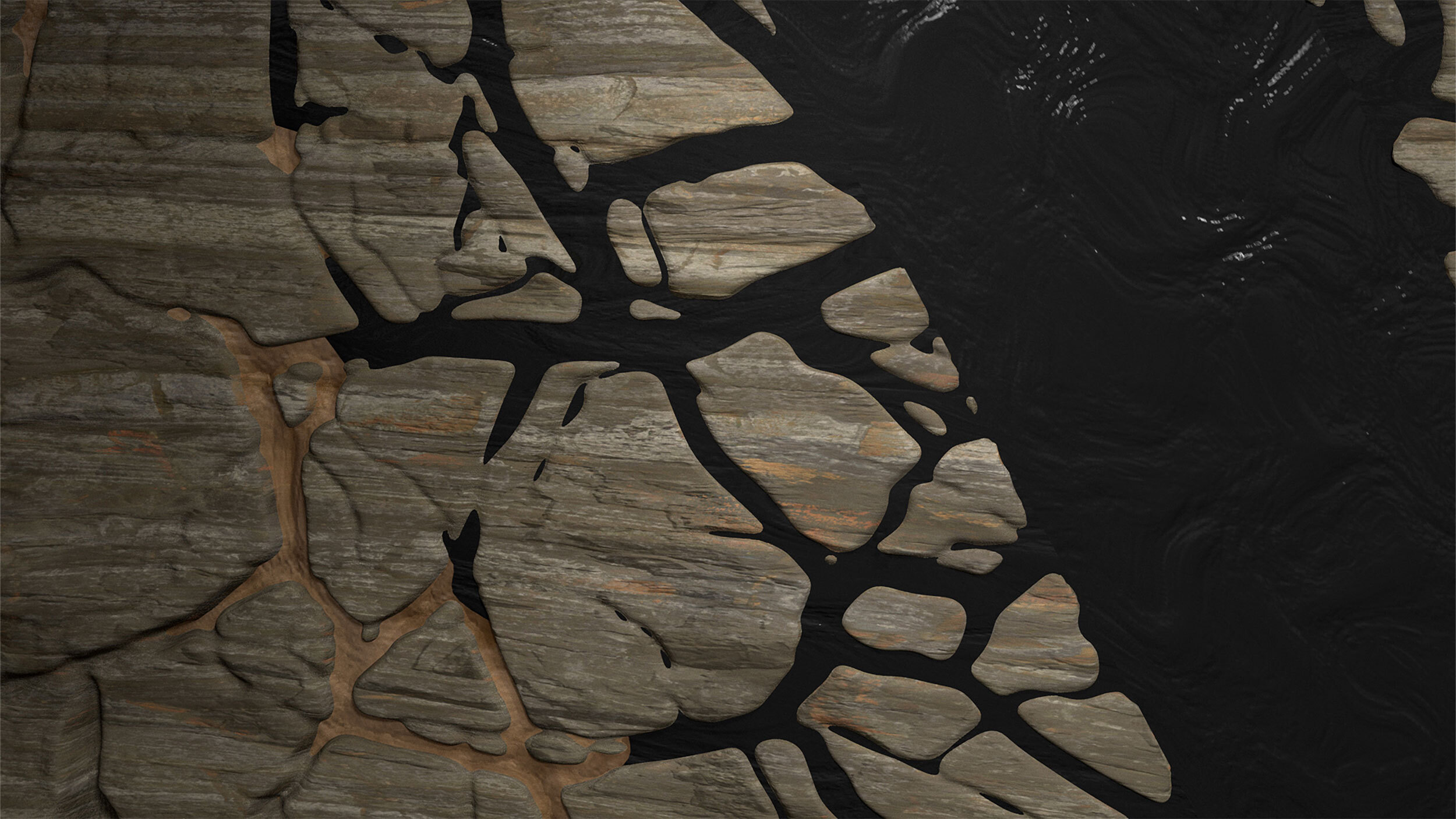

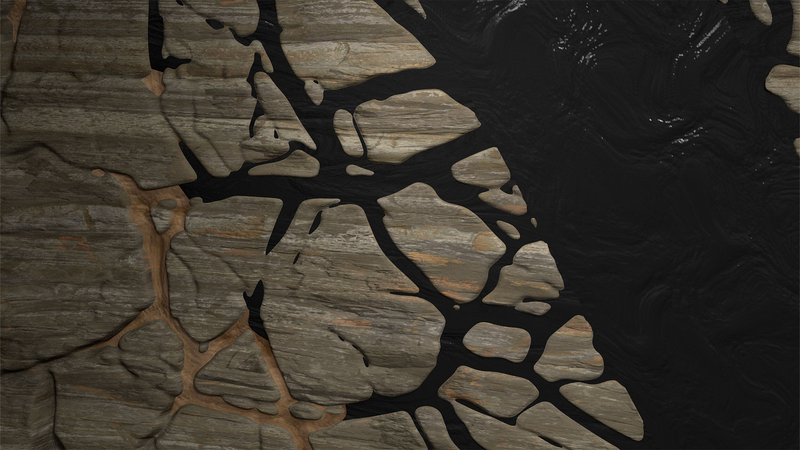

Severe to total lost circulation in vuggy zone behind casing

Iraq

A mature oilfield in southern Iraq presents challenges with reservoir pressure decline and high water cut in the Mishfrif formation. Much of its remaining recoverable oil is locked in complex geological formations. Deployment of large-scale engineered solutions, such as conformance treatments, to isolate the lower Mishrif subinterval is a challenge because of total lost circulation in a vuggy carbonate formation behind the perforated interval.

The operator needed to isolate perforated intervals to explore new prospects in a key reservoir for future production. The reservoir presented several challenges. High permeable zones with unpredictable well responses made curing losses time-consuming. Complex job requirements that included channeling behind the casing and difficulty tagging cement led to low success rates in Class III and IV wells. Additionally, the presence of acid wormholes and vuggy zones from historical acid stimulations absorbed cement and required treatment for lost circulation to be sealed off.

Historically, various methods, such as conventional lost circulation materials (LCMs), thixotropic cement systems, and multiple cement plugs, were attempted to address such issues with limited success.

Halliburton proposed a tailored solution using SentinelCem™ Pro cement system to isolate the perforated, loss-prone, highly permeable vuggy zone. SentinelCem Pro cement is a highly thixotropic single-sack lightweight system that develops rapid gel strength when static and returns to a liquid when shear rate is applied. This property helps cure the losses deep into the loss zone. Part of the treatment is left inside the casing to maintain well integrity after the treatment is drilled out.

Tuned® Defense™ cement spacer, a specialized lost-circulation cement spacer, was first pumped downhole. The cement spacer was supplemented with BridgeMaker™ II LCM to further enhance the success rate and suppress losses. SentinelCem Pro cement system, supplemented with BridgeMaker II LCM, was pumped downhole after the spacer. The tailored solution required rigorous engineering, which included computer-aided simulation, laboratory testing, and field testing before implementation.

psi pressure test confirmed isolation

Leaks into the perforation during drilling

Successful isolation

Before the cement operation, the well experienced total losses, evident by the low fluid level. The eco-meter gauged the fluid level before and after the SentinelCem Pro cement application. Post-job, the fluid level rose to the surface, which indicated a successful cure for the losses. Part of the SentinelCem Pro cement system was squeezed into the perforations. While drilling the plug, the cement remained intact without any leaks into the perforation. After drillout was complete, a pressure test at 1,500 psi confirmed the integrity of the SentinelCem Pro cement, which demonstrated successful isolation of the perforations, and all objectives were achieved.

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Improves cement spacer designs to prevent lost circulation.