BHKA™ plug setting disconnect tool increased operational efficiency as part of deepwater deviated well-abandonment operation

Download PDFDeepwater well-abandonment

Isolate deviated wells as part of well-abandonment campaign

Africa

Plug and abandonment (P&A) operations are complex and often require the placement of several cement plugs to meet isolation objectives. This process can limit the cement fluid design, can lead to excessive wait-on-cement (WOC) time, and can be time-consuming and costly when mandatory or controlled by government regulations.

A major operator asked Halliburton to help plan a five-well, deepwater P&A campaign in southwest Africa. The P&A design involved a variety of isolation lengths (up to 935 m) and well deviations (up to 85°).

Conventional placement of balanced cement plugs for this scope would present several execution risks that push the boundaries of cement plug best practices, such as plug length, plug stacks, and cement fluid design. Zonal isolation was necessary to allow future well operations, and the deepwater environment added costly and time-consuming operations to trip the work string and WOC.

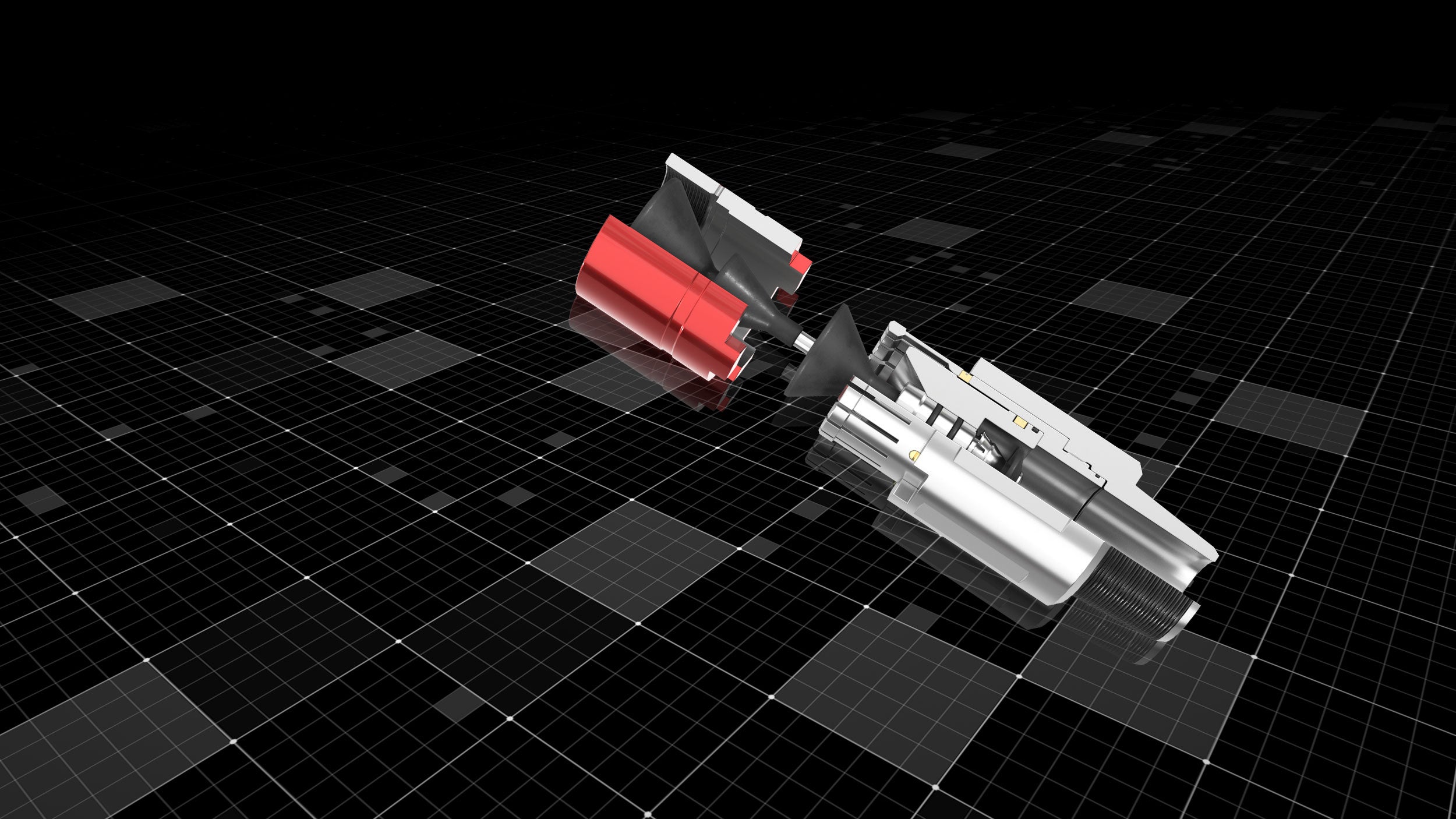

Halliburton evaluated the technical complexity of the campaign and recommended a combination of the BHKA™ plug setting disconnect tool and sacrificial tailpipe. This solution significantly reduced the complexity and challenges of standard balanced plug cement operations. The BHKA plug setting tool uses a Halliburton MCXV displacement dart. This process enables fluid separation down the string, allows for safe disconnection of the tailpipe stinger from the work string, and shears retaining pins with surface-applied pressure. The mechanism quickly releases the downstream tail pipe to provide a clear surface pressure indication and eliminate the need to pull the string out of the cement plug length. As a result, there is no cement plug disturbance, and the risk of cement contamination is minimized.

Spotting a single cement plug across a sacrificial pipe eliminates one of the main risks associated with cement plug operations—contamination. This allows aggressive cement slurry design, often difficult to achieve with standard plug operations, for quick compressive and gel-strength development. In addition, the single cement plug design eliminates the need to pull out of hole (POOH). This removes WOC time for multiple stacked plugs and reduces WOC time for the single plug because the slurry design is less conservative.

Well campaign proceeded ahead of schedule

Days rig time savings

USD saved

The clear tailpipe release at the end of plug displacement minimized fluid contamination and enabled a successful cement operation on the first attempt. The BHKA plug setting disconnect tool helped deliver an efficient and effective abandonment operation and reduced time and exposure to risk and environmental impacts associated with contaminated fluid after each cement plug. The tool reduced rig operational time by approximately seven days and saved over USD 6.5 million. This success enabled the operator to proceed with campaign development ahead of schedule.