Innovative cement systems and mechanical barriers to mitigate sustained casing pressure

Talk to an expertFugitive emissions are a major contributor to greenhouse gas (GHG) emissions and in oil well cementing indicate that sustained casing pressure (SCP) has occurred. Caused by gas or fluid migration through a leaking cement sheath in one of the well’s annuli, SCP affects more than 30% of wells globally and can lead to fugitive emissions, loss of production, and costly remediation. Mitigating fugitive emissions is critical to wellbore integrity and key to deliver a sustainable cementing solution.

Our technologies to mitigate fugitive emissions include innovative cement systems, additives, and mechanical barriers.

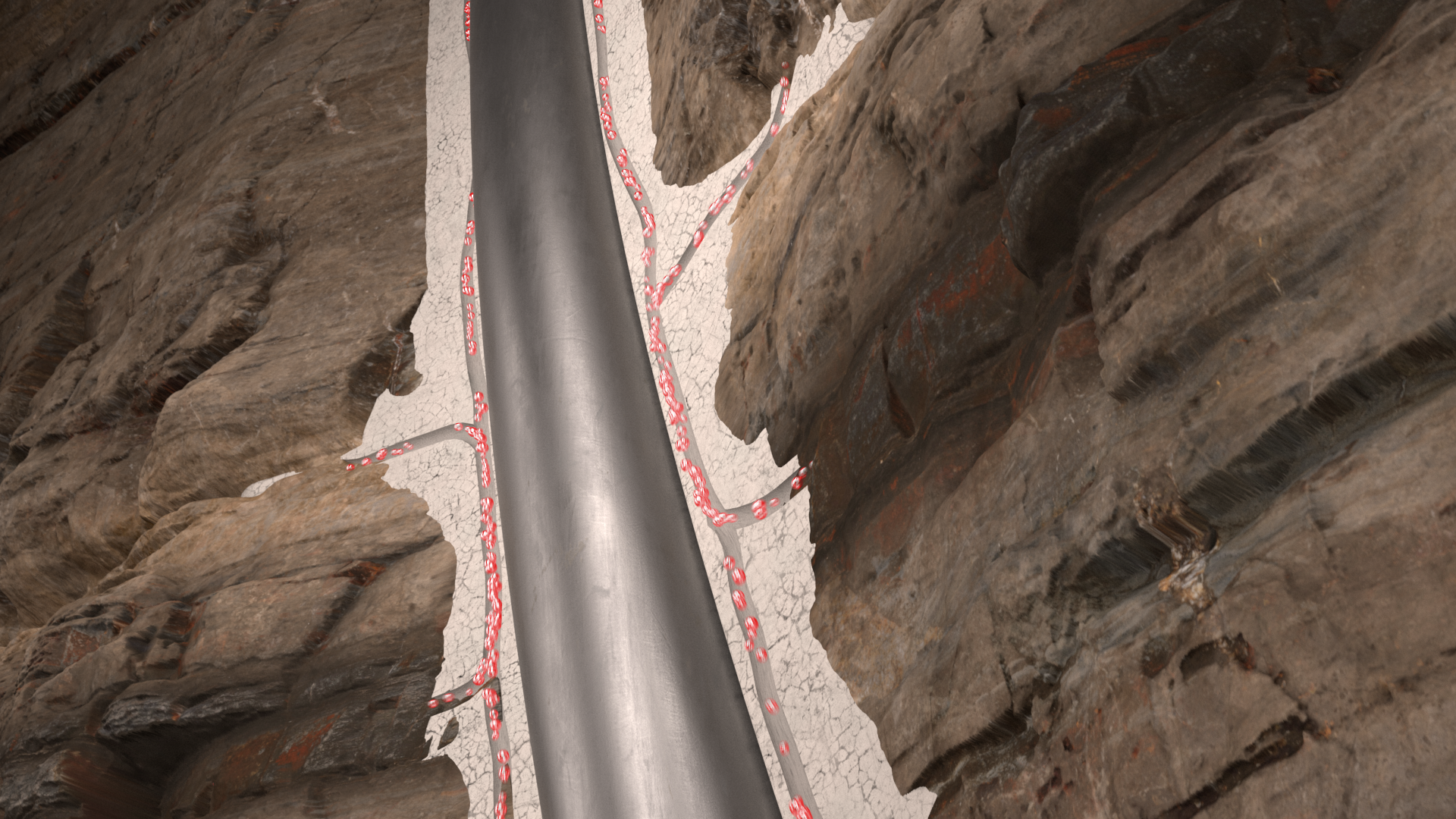

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.

IsoGuard™ cement additive mitigates annular flow through unset cement by providing excellent fluid loss control and shortening transition time.

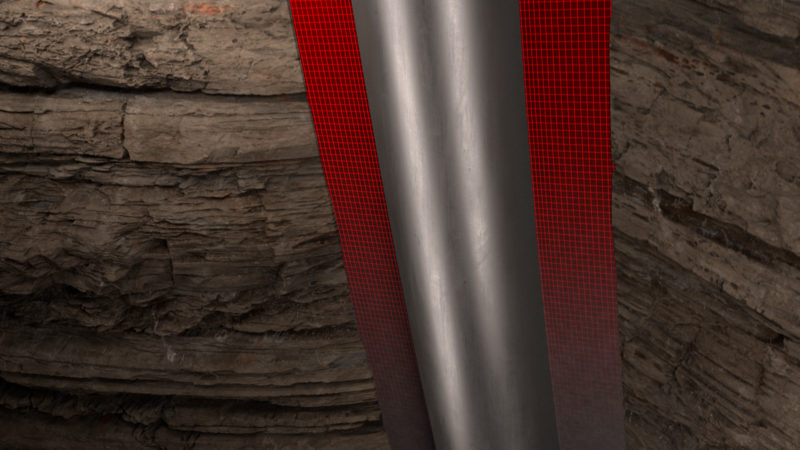

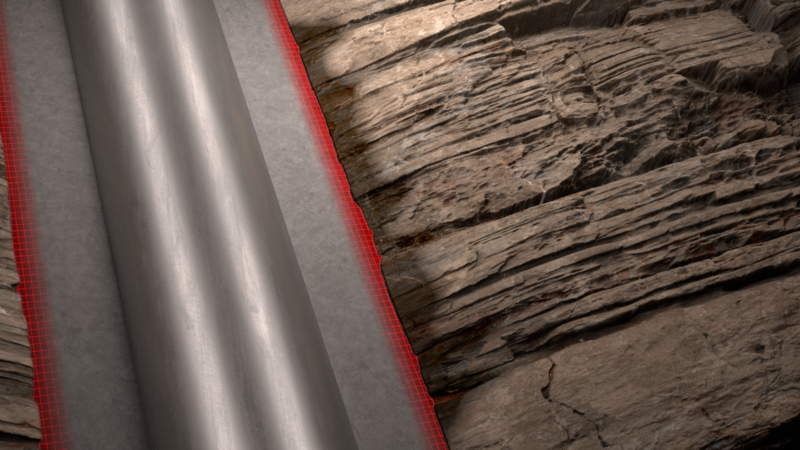

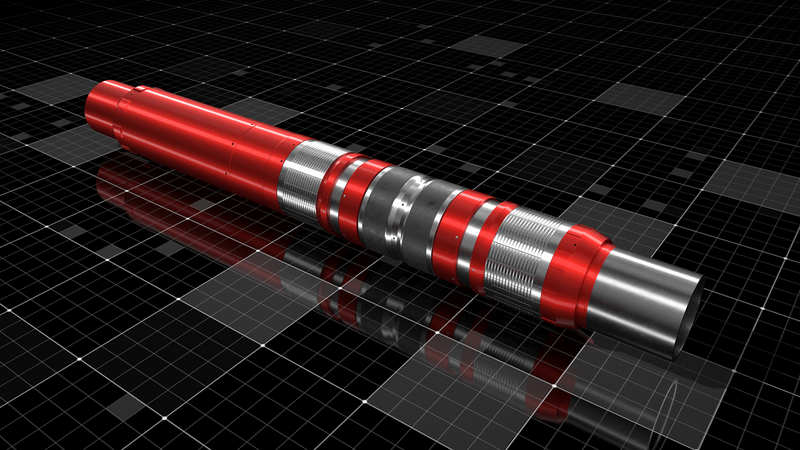

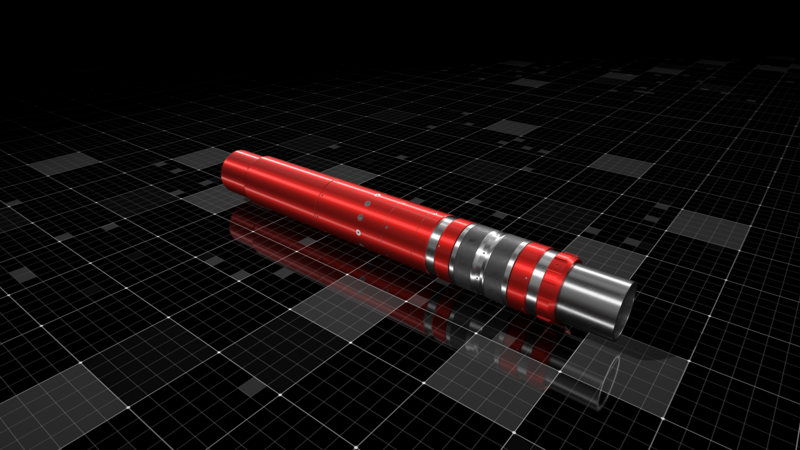

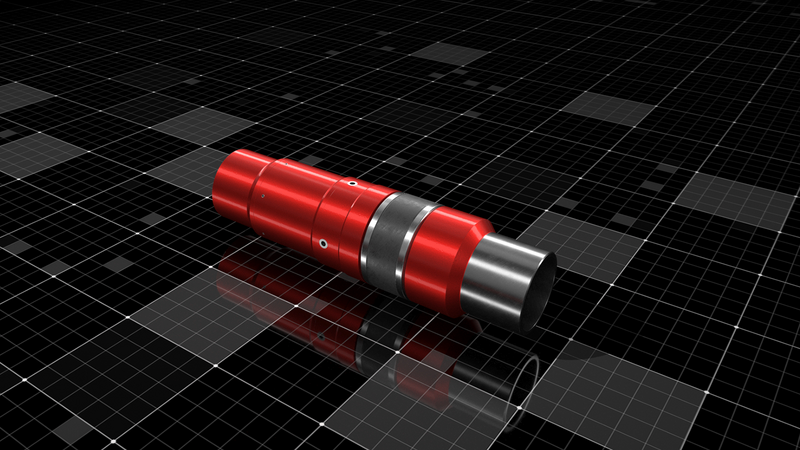

The Obex GasLock® casing annulus packer provides a high-pressure, gas-tight, casing-to-casing seal to mitigate annular gas migration.

The Obex IsoLock® packer collar provides V3-rated mechanical barrier support plus integral second-stage cementing capability.

The Obex EcoLock® casing annulus packer provides mechanical barrier support to prevent low pressure gas or fluid migration.