A solution to address stuck ball valves that cannot be mechanically shifted

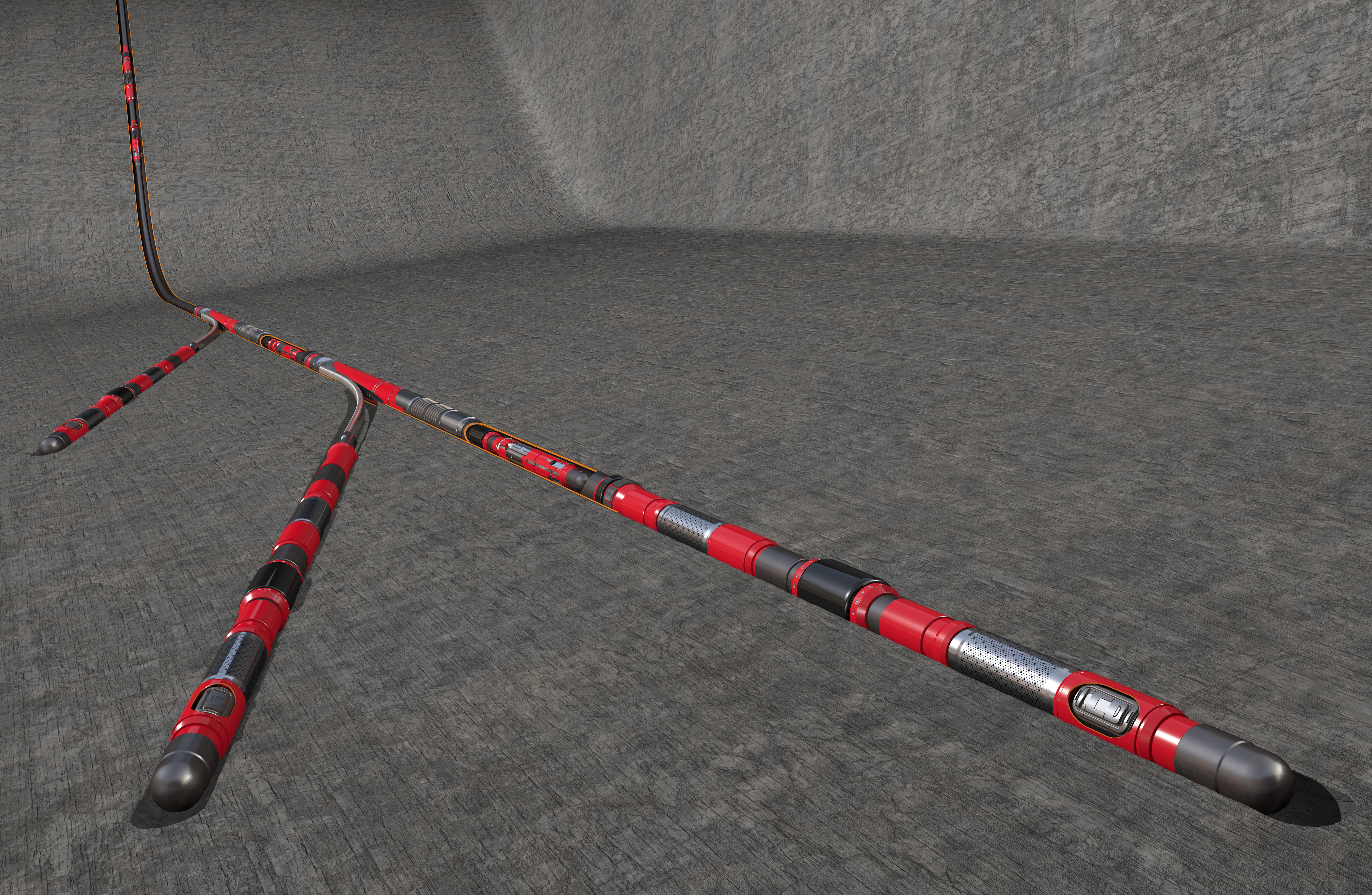

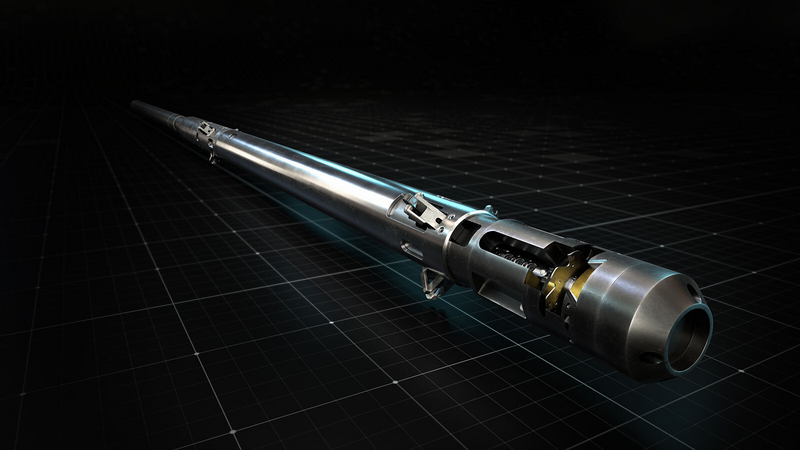

Talk to an expertThe ClearMill™ electro-mechanical miller is a high-performance, e-line milling solution powered by advanced electro-mechanical technology. Designed for complex downhole interventions, it delivers precise and efficient milling of stuck ball valves in barrier isolation systems, closed subsurface safety valves, flapper valves, permanent plugs, stuck locks, nipple profiles, and ball seat repairs. The system is optimized for challenging materials to ensure reliable performance in complex well environments. The apparatus integrates three core modules—the anchor, actuator, and high-torque rotary unit—which support four specialized mill-bit designs tailored to diverse applications. With a compact 2.25-in. run-in-hole (RIH) outer diameter, the tool navigates through all barrier isolation valves. The robust construction of the anchor module provides stabilization during high-torque downhole interventions. Equipped with three 3 × 1-in. pads, it is configurable for two RIH profiles to accommodate a broad range of tubing sizes. The high-precision actuator module delivers controlled force for complex downhole interventions. It enables accurate milling of failed completion devices, to include stuck ball valves, plugs, and locks. The high-torque rotary module is a critical component in the milling configuration. Engineered for efficiency and versatility, it supports multiple bit designs tailored for diverse applications and delivers precise material removal in complex environments, which includes 718 Inconel ball valves. The ClearMill electro-mechanical miller joins a dynamic electro-mechanical portfolio of innovative solutions for downhole challenges, which includes ClearTrac™ e-line tractors, ClearCut™ cutters (single blade, rotary blade, and slim 1 11/16-in.), ClearBail™ suction bailers, and ClearShift™ high-expansion shifters.

Minimum ID restriction

Tool weight

Maximum temperature

Inconel ball valves

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.