StrataStar® service improves well placement and boosts production by ~10%

Download PDFDeepwater

Trajectory control struggles with heterogeneity, poor sand, and water drive

China

Oil Field A, located in the Pearl River Mouth Basin in the South China Sea, presents challenges because of unconsolidated reservoirs and complex geology. Development is complicated by active bottom water and poor consolidation. This increases risks related to well trajectory control and reservoir management. To maximize hydrocarbon recovery, Halliburton deployed a high-definition reservoir mapping technology to increase contact with high-quality sand layers and avoid water interaction in seven horizontal wells.

The primary sand Reservoir H presented vertical and lateral heterogeneity with poor consolidation that increased the potential for borehole collapse and washouts. The active bottom water drive added complexity to well trajectory control and made water encroachment difficult to avoid. Traditional tools proved insufficient to visualize and map reservoir structures. Advanced technologies were necessary to overcome these difficulties and facilitate optimal well placement.

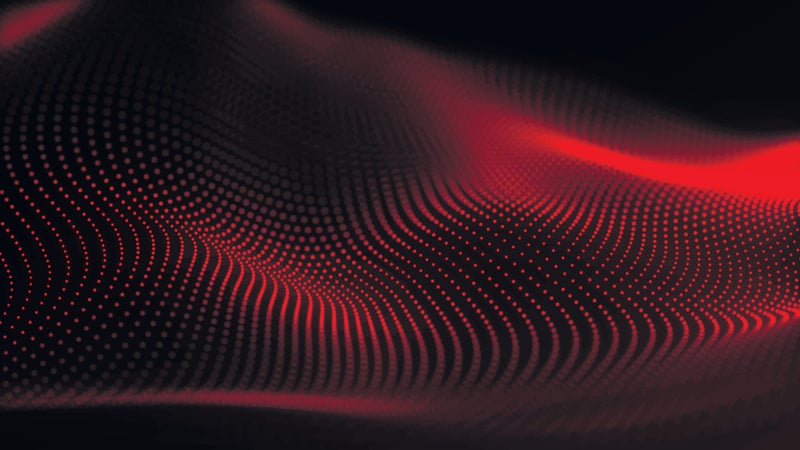

Reservoir-H: Real-time 1D inversion canvas shows sand lobe lateral variation and distribution of high (red) and low (blue) resistivity 8 m near the wellbore.

The integrated solution involved high-definition, multi-layer reservoir mapping technology with the StrataStar® deep azimuthal resistivity service. This technology enables visualization of up to 9 m to provide real-time insights into the reservoir structure, oil-water contact (OWC), and sand distribution. A point-the-bit rotary steerable system (RSS) enhanced wellbore quality and trajectory control with minimized side forces on the drill bit, and maintained stability in unconsolidated formations. The optimized hydraulic design reduced flow rates and optimized the bottomhole assembly (BHA) to prevent borehole enlargement and facilitate drilling efficiency.

High-definition mapping provided detailed visualization of vertical and lateral reservoir boundaries. This enabled precise well trajectory adjustments during drilling. The deployment of seven horizontal wells resulted in a penetration of 2,970 m with a 100% contact rate in high-quality sand layers. This facilitated optimal hydrocarbon recovery, and the project production exceeded expectations by 10%. Lateral distribution of the top sand lobe was identified with a multi-well StrataStar® service 1D resistivity inversion comprehensive interpretation. This corrected the structure and provided a strong basis for subsequent well placement.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.