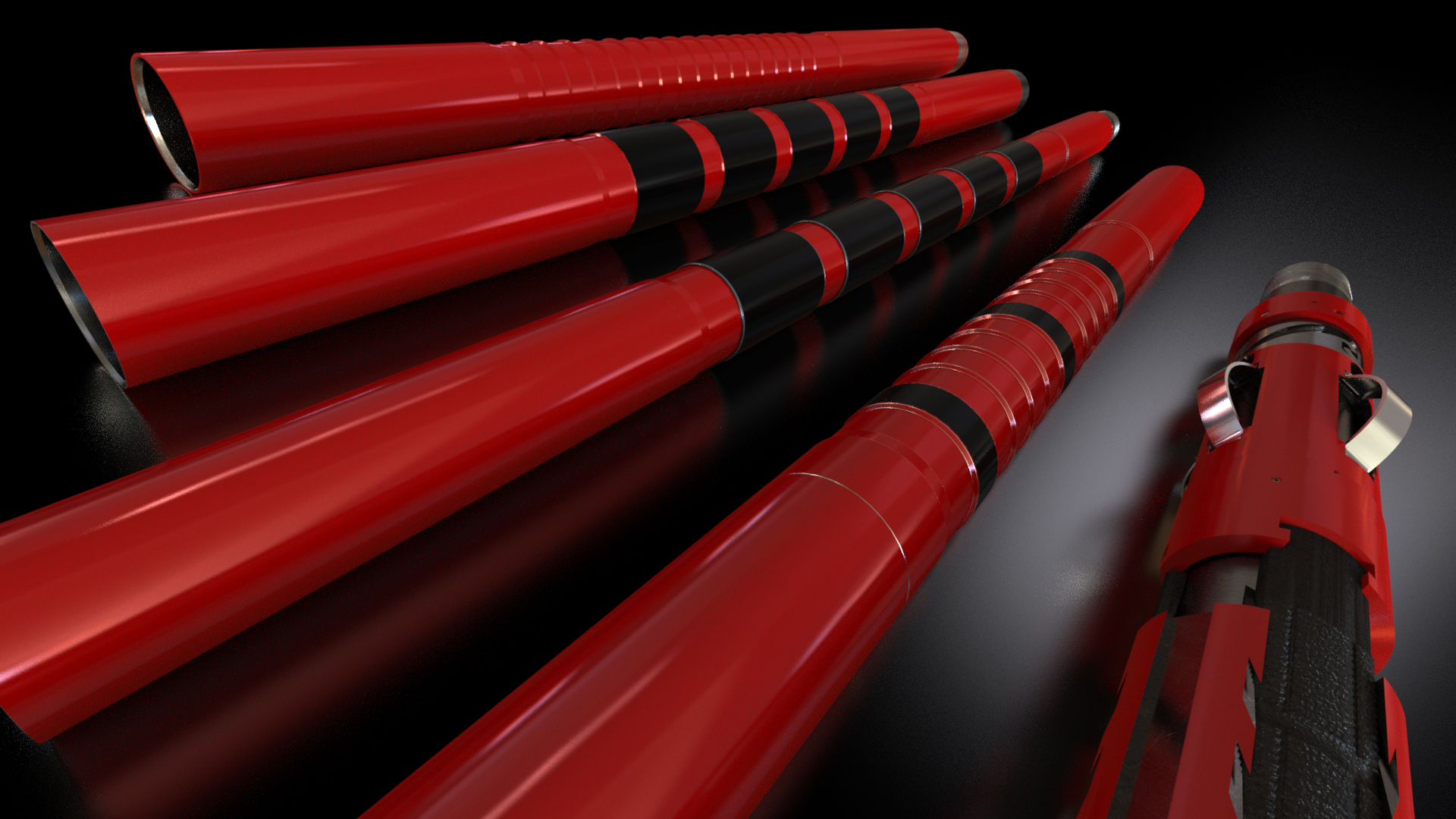

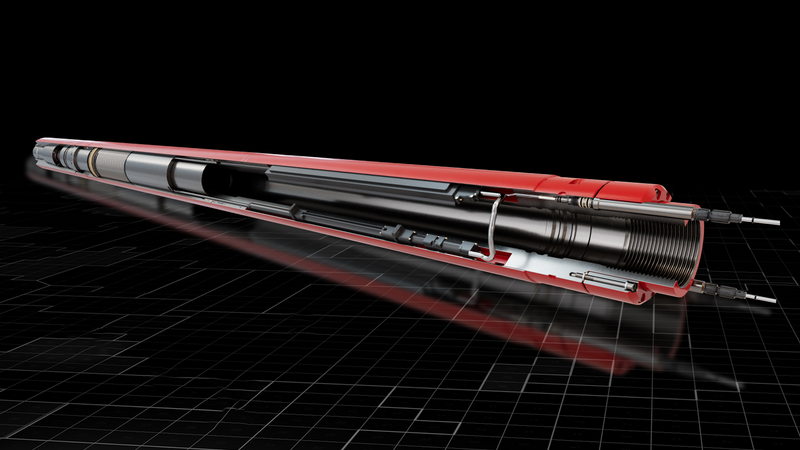

EcoStar® electric tubing-retrievable safety valve

Talk to an expertIn the oil and gas industry, efficiency and reliability are paramount, especially during emergency shutdowns (ESD). EcoStar, our advanced equipment, offers significant benefits and savings for operators, particularly when dealing with well issues that necessitate shutting in and recharging an umbilical. Let's explore how EcoStar can bring additional value to our customers.

Consider a field with six wells, each producing around 10,000 barrels daily. When an ESD occurs, the length of the umbilical plays a crucial role in determining the downtime and associated production losses. For instance, with a 30km umbilical, the conventional system's charge and vent times result in a production loss of nearly 13,000 barrels, equating to $838,000. In contrast, EcoStar significantly reduces this downtime, bringing the wells back online faster and cutting the lost revenue to $146,000. This translates to an additional $700,000 in production for that day alone.

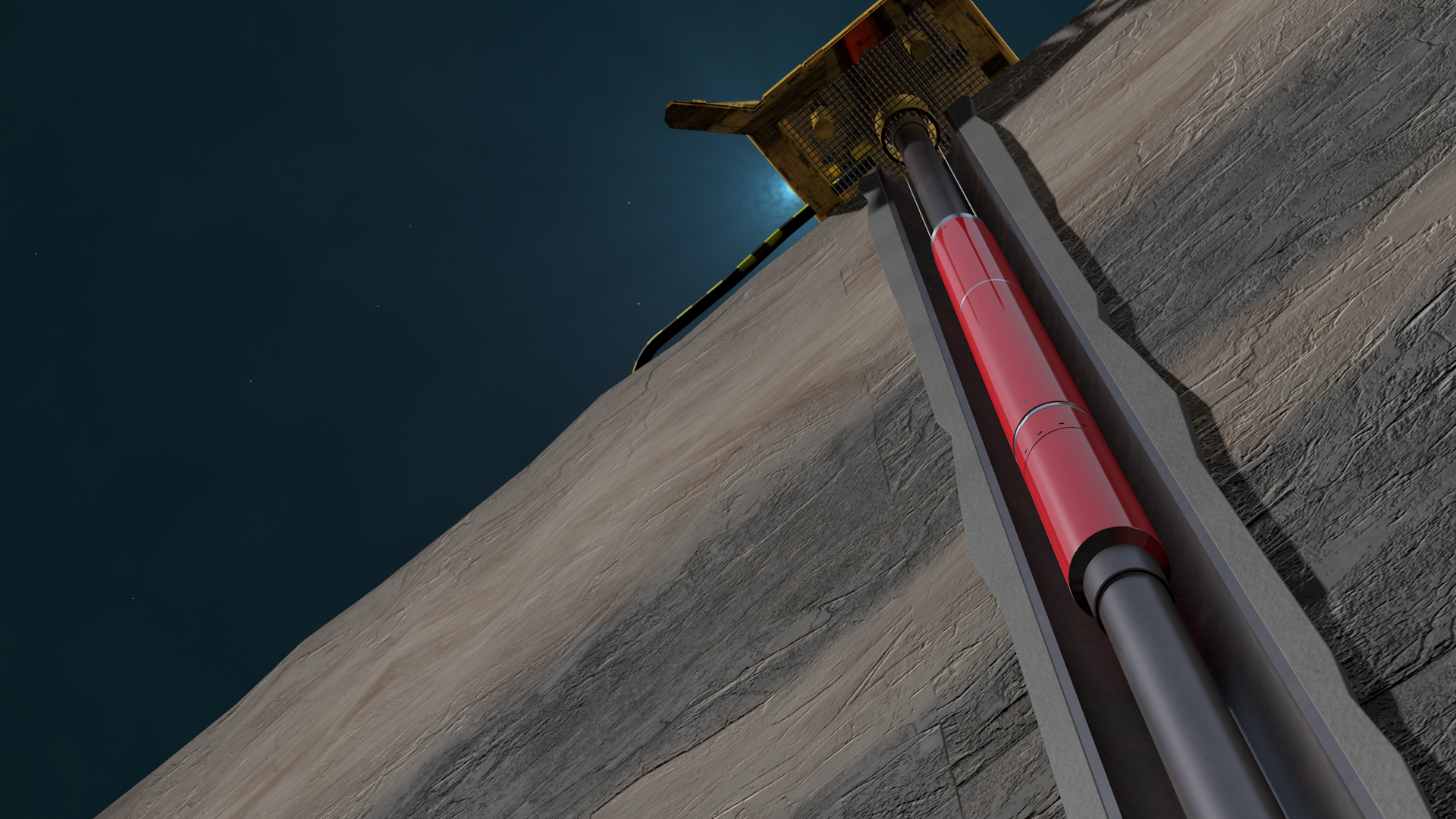

One of the standout features of EcoStar is its consistent performance, regardless of the umbilical length. Whether the umbilical is 15km or 50km, EcoStar operates with the same efficiency due to the speed of electricity, unlike conventional systems that rely on compressible fluids. This consistency provides operators with more predictability in managing shut-in times, enhancing overall operational efficiency.

Operators often face multiple ESD events annually, coupled with regulatory requirements for shut-in tests of the safety valve system. Over a year, these events can lead to significant production deferment. EcoStar's ability to minimize downtime during each shut-in event means operators can reduce production losses and increase revenue consistently. The cumulative effect of these savings over multiple events is substantial, making EcoStar a valuable asset for any operation.

EcoStar systems are designed for a lifespan of over 20 years, ensuring that customers benefit from their speed and efficiency year after year. This long-term reliability not only enhances operational stability but also contributes to sustained financial savings and increased production over the equipment's lifetime.

In conclusion, EcoStar offers a compelling combination of efficiency, reliability, and cost savings. By reducing downtime during emergency shutdowns and providing consistent performance across various umbilical lengths, EcoStar helps operators maximize their production and revenue. Investing in EcoStar means investing in a future of enhanced operational efficiency and long-term financial benefits.

World’s first electric tubing-retrievable safety valve, enabling a fully electric completion system with zero risk of exposing electronics to wellbore fluid.