LOGIX® drilling performance optimizer uses AI/ML to improve ROP and reduce well delivery time

Download PDFUnconventionals

Maximize ROP, cut well delivery time, and optimize drilling in harsh formations

Middle East

The upper Shuaiba formation requires customized drilling and subsurface solutions to maximize the operator’s asset value. This field’s drilling environment is characterized by sudden changes in rock hardness where any delays in the adjustment of operational parameters can impact drilling efficiency. These challenges can lead to a significant decrease in rate of penetration (ROP) and increase the risk of drilling dysfunction — such as downhole vibration, tool failures, accelerated bit wear, and unplanned trips to the surface, — all of which lengthen well delivery times.

A key factor in the management of these obstacles is the implementation of a multi-well automation and remote operations platform that features an automated drilling optimization service. This system has played a vital role in the reduction of well delivery times and minimized nonproductive time (NPT) with execution.

The Upper Shuaiba formation presents significant challenges with the optimization of drilling parameters, particularly in the curve section. This is characterized by interbedded formations and the lateral section, and requires well placement in a thin reservoir with the goal of maximization of the ROP.

The 6 1/8-in. lateral section involves drilling within a thin reservoir, with a high risk of exit into denser formations. Drilling in this section is further complicated by the need to manage high vibration, and requires careful operation within limited parameters to prevent equipment damage and maintain drilling efficiency.

The consistent and efficient management of drilling parameters and setpoints has been essential in the optimization of bit/rock interaction to maximize ROP and extend bit life throughout the run. To drill the 6 1/8-in. lateral section in the reservoir, the operator deployed the LOGIX® drilling performance optimizer. This service uses machine learning algorithms to auto-calibrate bit-rock interaction signature models, and calculate drilling efficiency across regime zones. It provides automated drilling parameter setpoints to enhance performance, maximize ROP, and automatically manage drilling dysfunction with exception alerts sent to multi-well remote operations engineers.

The drilling performance optimization provided by the LOGIX ® platform calculated the bit depth of cut (DoC) and real-time operational drilling efficiency, and provided the most optimum drilling parameter setpoints to maximize drilling efficiency and ROP. The machine learning algorithms calculated apparent rock strengths and adjusted operational parameters to keep the bit cutters engaged, and ensured effective rock cutting, and the maximization of drilling efficiency.

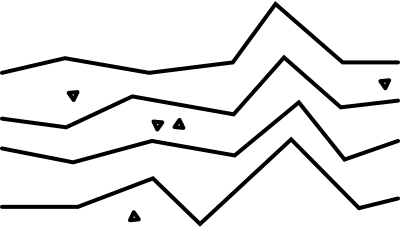

Figure 1 compares the subject well (Well 1) to offset wells drilled with the same rig on the same pad. The subject well was drilled with the advanced algorithms of the LOGIX® platform. The driller’s roadmap was updated based on real time bit-rock interaction calculations to achieve the best drilling performance in terms of ROP and the longest lateral section drilled on the path.

Figure 2 compares the WOB and DoC of Well 1, and setpoints were provided by the LOGIX® platform. Automation services were not deployed in Well 2. This well was the best offset of the subject well. The average WOB in Well 1 was more consistent and delivered 15% higher DoC. As a consequence, higher ROP was achieved, as shown in Figure 3 and highlighted in chart intervals ROP-A and ROP-B.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.