Accurately manage multiple interval control valves with minimal lines

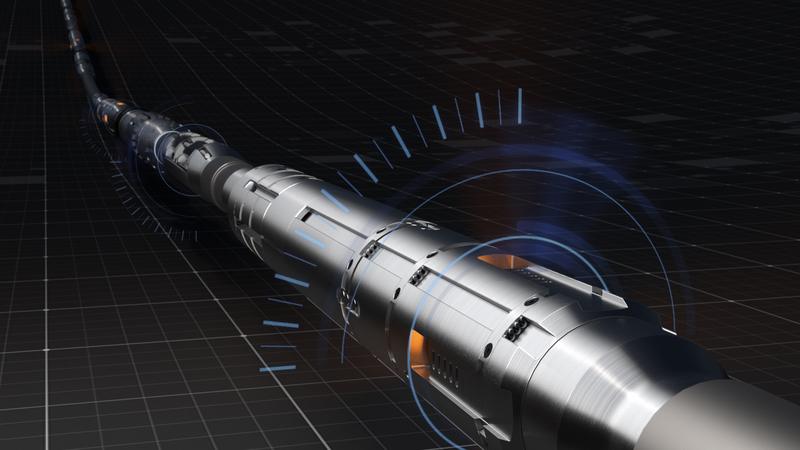

Talk to an expertThe SmartPlex® downhole control system is an electro-hydraulic multi-drop system that provides simple and reliable zonal control of multiple valves in a single wellbore with a minimum number of control lines. The SmartPlex downhole control system uses two hydraulic and one electric line from the surface to remotely and selectively actuate multiple downhole flow control devices, such as interval control valves (ICVs). This makes a significant number of tubing hanger penetrations unnecessary and reduces operational complexity and risk. The SmartPlex system can control any flow control tool in the field-proven Halliburton portfolio. The SmartPlex control system has been successfully deployed and field trialed in a multi-zone completion. Thanks to this system, the operator can now achieve maximum reservoir control from multiple laterals with minimum system complexity.

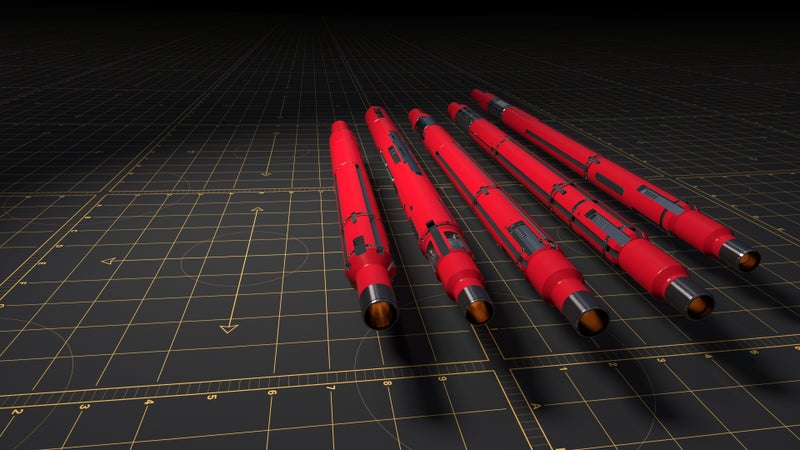

The SmartPlex® downhole control system is applicable for any dry-tree multizone completion that requires more than two valves. The SmartPlex system not only helps reduce the overall cost of an intelligent completion, but also reduces the complexity involved by minimizing the number of control lines required. Ideally suited for long horizontal, compartmentalized completions (as deep as 30,000 ft), in both cased or open hole, where selective control of each interval is desired. Typically, this can be advantageous for selective stimulation control in tight-gas applications or in combination with a choking ICV for drawdown optimization in production applications.

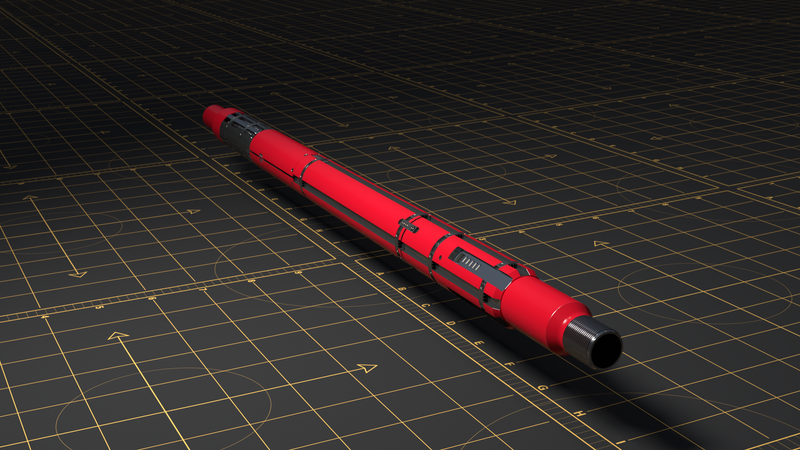

The SmartPlex system uses a simple passive electrical switching method. Each valve is coupled with a SmartPlex actuator module, which allows selective and remote control of each valve. Control lines consisting of one electrical and two hydraulic lines run from surface and are networked to each SmartPlex module.

A signal down the electrical line switches a solenoid at a desired module, allowing hydraulic communication between the surface control unit and the valve. By regulating the fluid volume in combination with a time-domain control method, valves can be incrementally positioned (choking) to allow for advanced reservoir management

The SmartPlex control system successfully passed extensive in-house deep well simulation testing. The tool was cycled more than 10,000 times at high temperatures and pressures. A nine-valve system integration test with 15,000-ft control line was also successfully conducted.

The direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices.

The Accu-Pulse™ module enables incremental opening of a multi-position ICV to control produced or injected fluid rates for enhanced reservoir management.

Digital Hydraulics™ is a multi-drop downhole control system that provides simple and reliable zonal control for even the most complex reservoirs

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore.

The debris-tolerant HS interval control valve (HS-ICV) enables deployment of Halliburton SmartWell® systems in high-pressure, deepwater environments.

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.