Increasing oil recovery at lower cost with washpipe-free ICD completions

Talk to an expertCompletions with inflow control devices (ICDs) have proven to increase oil recovery by balancing the flow of reservoir fluids. This balanced production delays the onset of gas and water while simultaneously encouraging oil production. Balanced production also improves the drainage of the reservoir with consequently higher oil recovery.

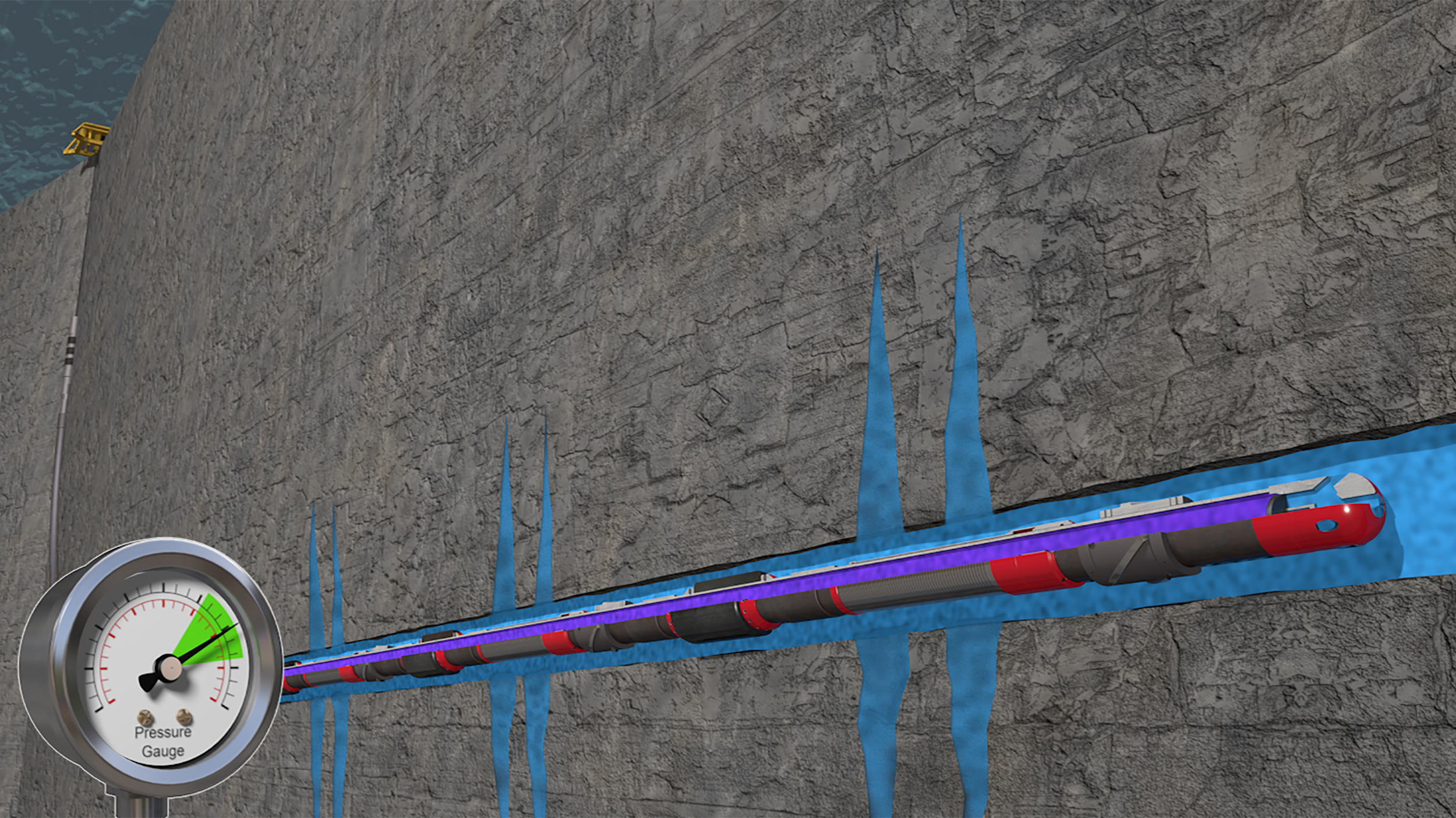

Running an ICD completion with washpipe provides the ability to circulate from the end of a bottomhole assembly (BHA) to assist in navigating through tight spots and over ledges. However, drawbacks with utilizing washpipe include operational time, cost, and risk. Time is required to make up the inner string and the risk of hole collapse, as the open hole remains open prior to reaching total depth (TD). Additionally, the risk of introducing debris to the wellbore from rusty or dirty washpipe, along with leaving parted washpipe in the hole, are both eradicated.

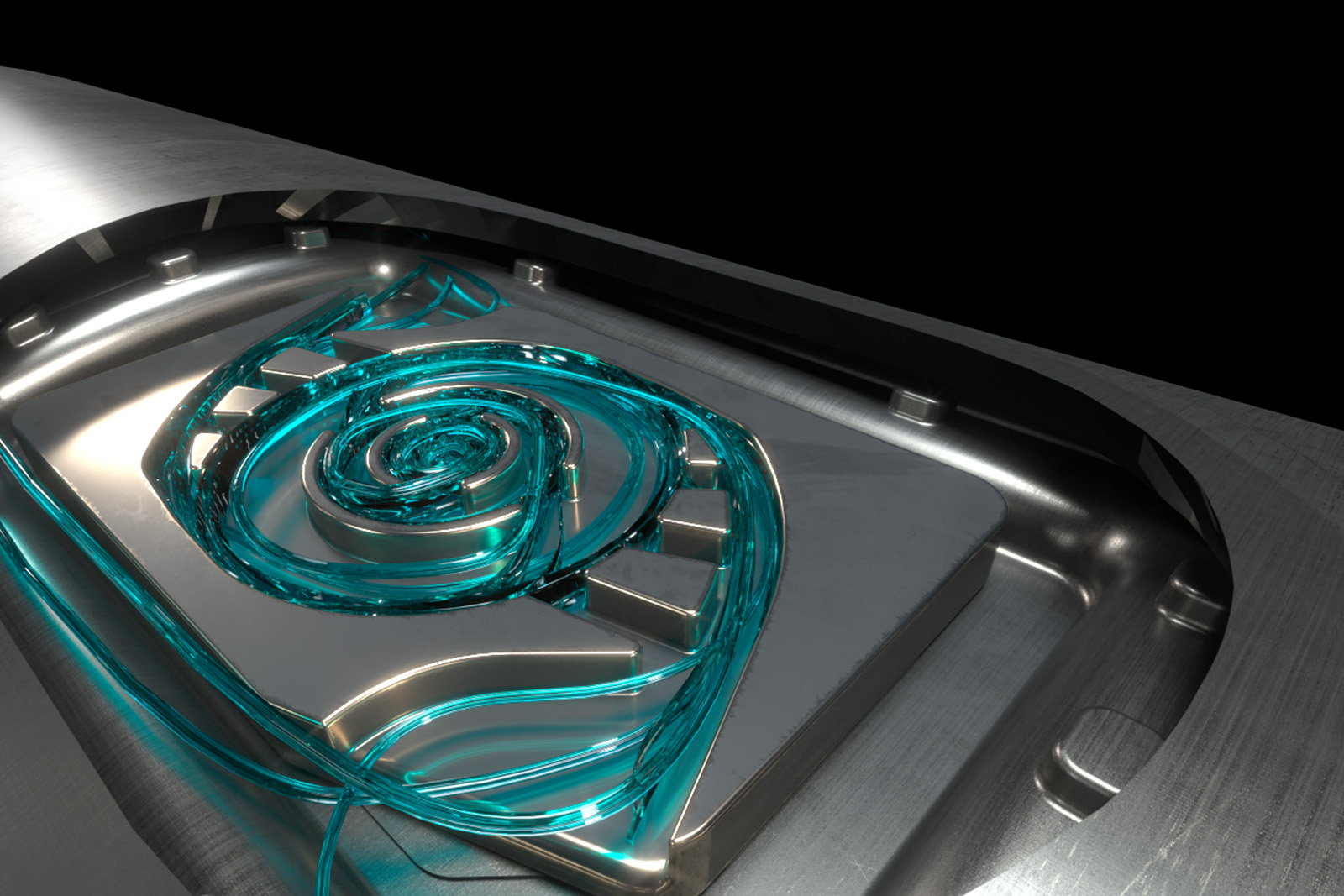

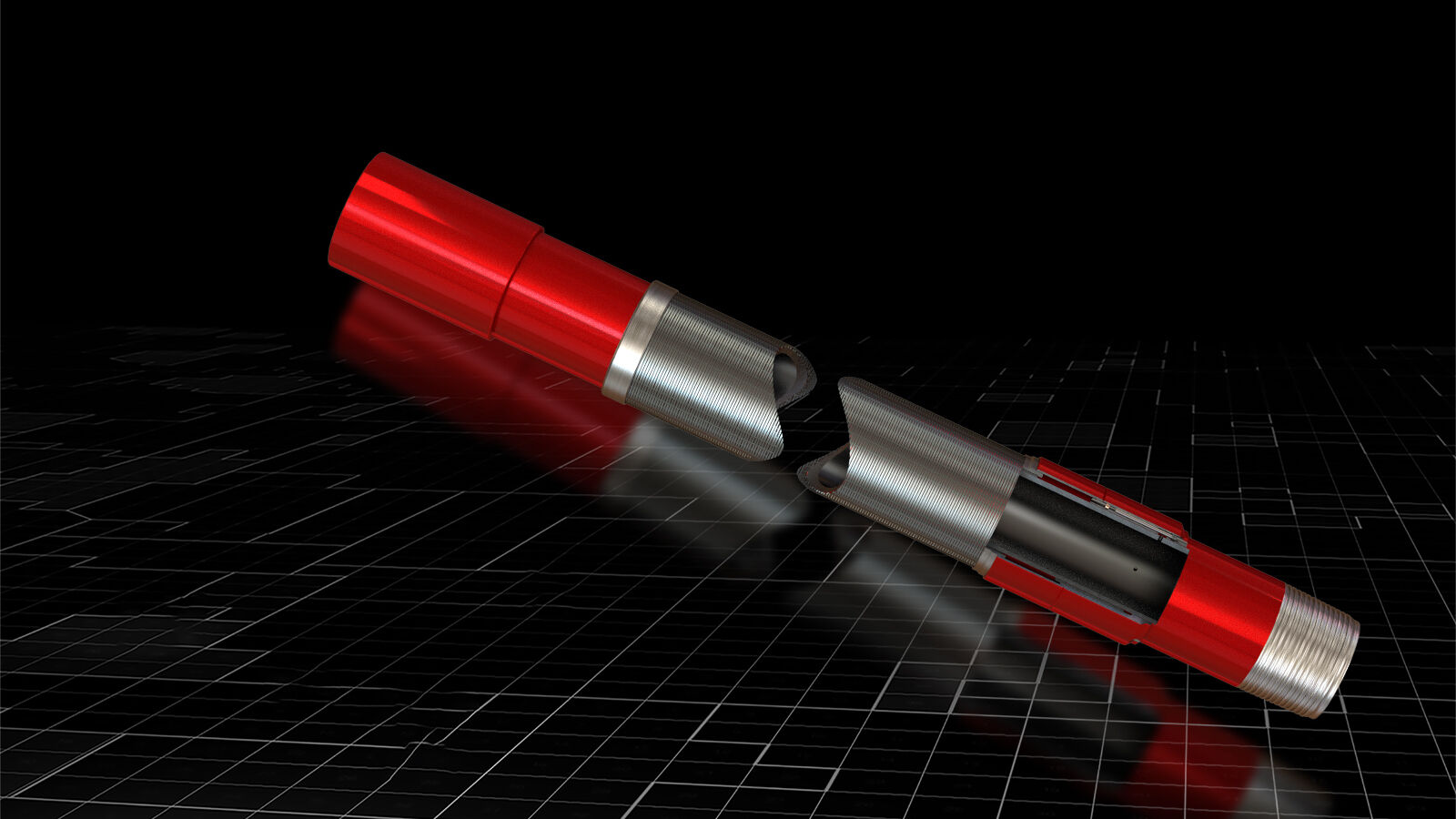

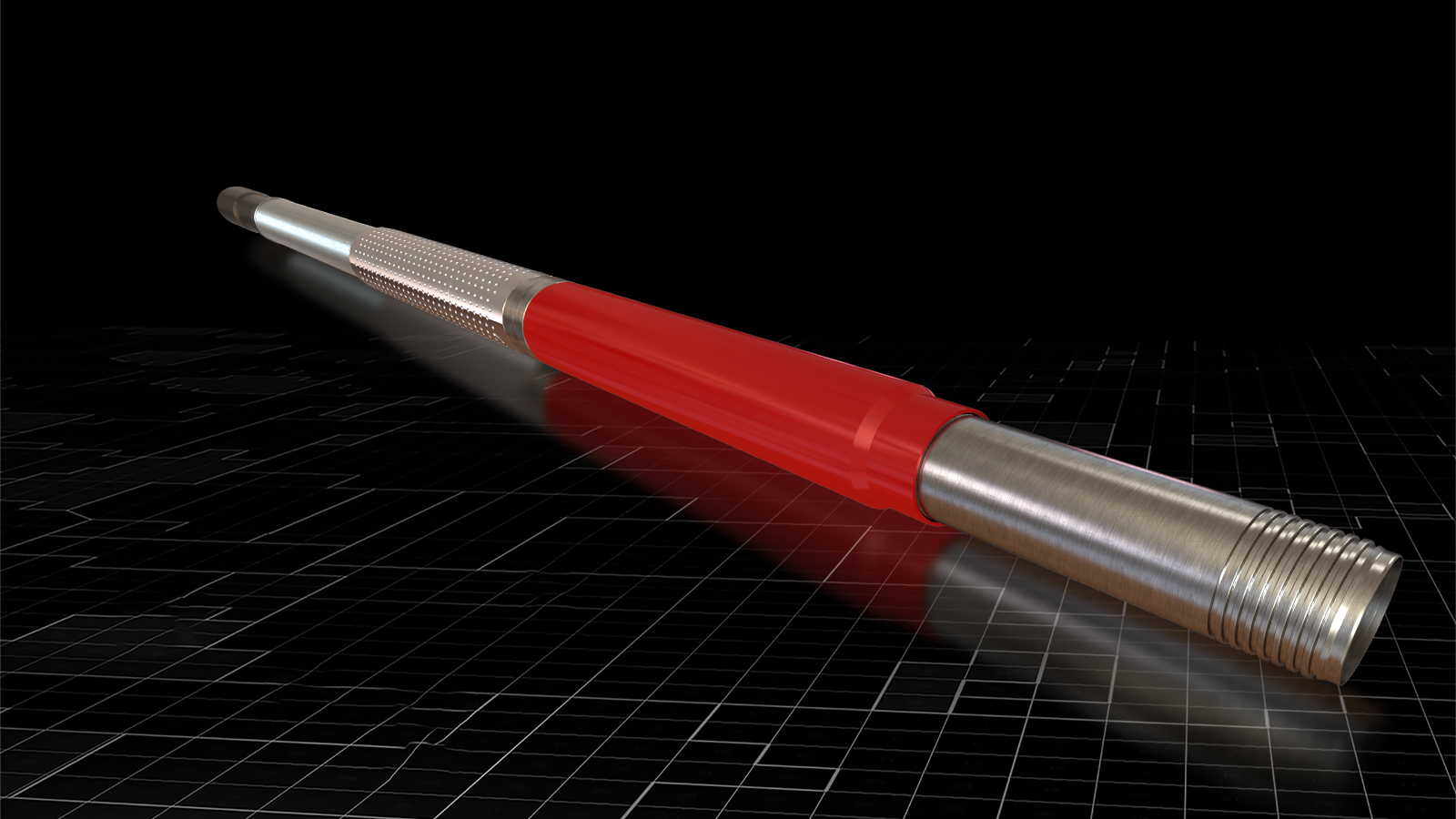

The innovative EquiFlow washpipe-free adjustable ICD uses plugging rods to adjust the flow settings through the device. Dissolvable rods can be used to plug the flow paths in the ICD housing, and they disappear after the completion is installed and fluid displacement is complete – thus, creating a washpipe-free ICD completion. Dissolvable plugs are available in a variety of metallic and non-metallic materials.

The most appropriate material is dependent on the non-reaction time period required, and what catalyst (fluid) will be utilized to dissolve the material and downhole conditions, such as reservoir temperature. The technology is available in a number of differing shapes and profiles to suit a variety of applications – all with the common goal of eradicating the requirement of a washpipe. The technology is specifically tailored to accommodate the fluid program, with respect to exposure to fluid types and the required operational timescales.

Balances production flow and restricts unwanted production fluid, even with minimal viscosity difference between the produced fluids.

Helps delay and reduce the flow of unwanted fluid and stimulates balanced production throughout the entire interval.

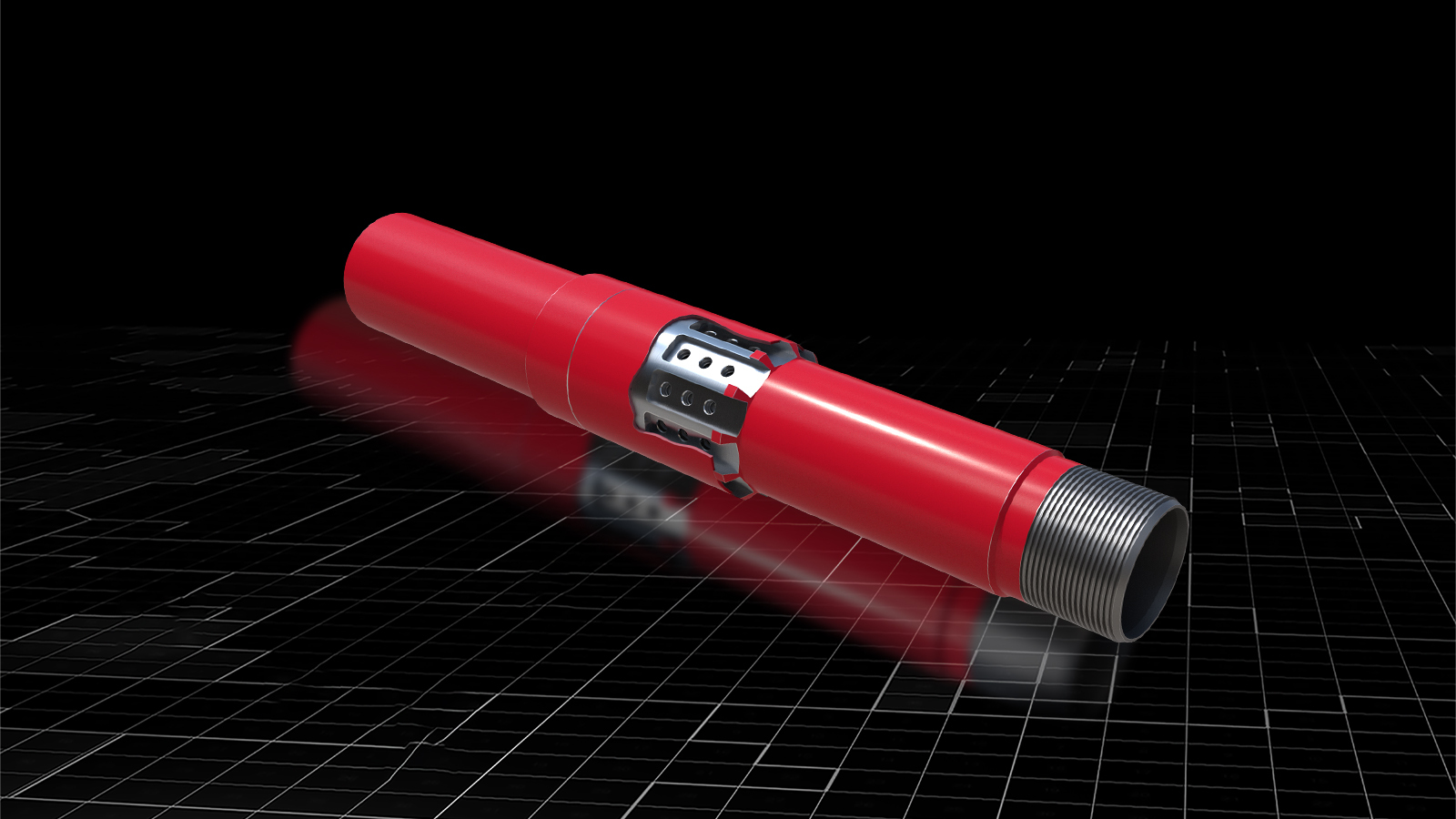

Combines the benefits of inflow balancing with the flexibility to reconfigure the ICD as needed.

The EquiFlow ICD with sliding sleeve combined with the PetroGuard® sand screen provide inflow control technology with a mechanical sliding sleeve functionality.

Maximize production efficiency and improve steam-oil-ratio in SAGD wells.

This solution is ideal for deepwater and extended-reach applications, which provides washdown capability and pressure integrity for operational requirements, such as fluid displacements or setting packers hydraulically. The technology has no moving parts and provides a pressure seal without any leak paths. This assures hydraulic flow and pressure requirements, which may not be the case in solutions that require a hydraulic actuation to make, or break, the potentially critical seal.

Dissolvable plug technology has been tested with a variety of materials, fluids, temperatures, and organic and inorganic acids, as well as common completion brines that are among the many suitable catalysts.