Electro-mechanical selectable shifter to mechanically override barrier isolation valves, ICVs, or completion devices that require manipulation

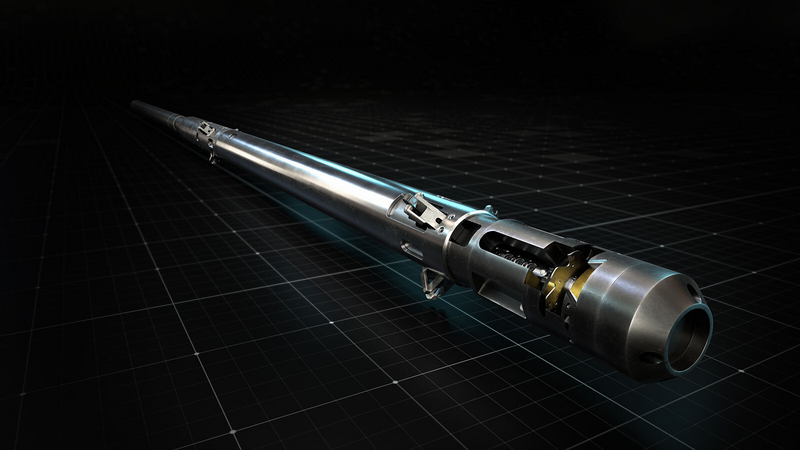

Talk to an expertClearShift™ service employs advanced electro-mechanical technology to handle contingency override scenarios in downhole completion devices. These include barrier isolation valves, annular isolation valves, lubricator valves, internal control valves, electromagnetic safety valves, and standard mechanical shifting requirements with DuraSleeve® sliding sleeve production apparatus and SSD non-elastomer circulation sleeves. ClearShift service has three distinctive sections: the anchor, actuator, and high-expansion shifter. The small run-in-hole (RIH) OD of 2.25 in. passes through all barrier isolation valves and offers selectability for multi-ICV scenarios where landing in the proper valve is critical. The anchor uses three large 3 × 1-in. pads and can be set up in a 2.25-in. RIH to cover pipe from 3.5 to 5.5 in. or a larger 3.3-in. RIH to cover pipe from 4.5 to 7.0 in. The large pad cross-sectional area allows the device to hold a radial force greater than 50 klbf to prevent slipping under load and still minimize indentation or slip mark impressions in the pipe.

The electrical feedthrough actuator has a stroke length of 2.2 in. with an accuracy of 0.25 in. and can pull up to 28,000 lbf. This allows the ClearShift service tool to open any device and close valves with a shear ring. The tool is designed with an electrical connection so any tool can be run below the actuator. The high-expansion shifter was designed to land into the contingency profile of the FS2, similar to the large-OD BS1 shifting tool. This feature ensures the shifter has sufficient surface area to lock in, which is critical if the FS2 must be closed. The 2.25-in. RIH allows the tool to pass through the small 7-in. and the larger 9 5/8-in. FS2 valves. ClearShift service is part of the powered electro-mechanical portfolio, which includes ClearTrac® wireline tractor service, ClearCut® slim, single- and rotary-blade cutters, ClearBail suction bailer service, and ClearMill milling service.

Actuator force

Tool weight

Maximum temperature

Tool outside diameter

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.