Maximize efficiency and reduce fuel costs and emissions with high-performance gas fracturing

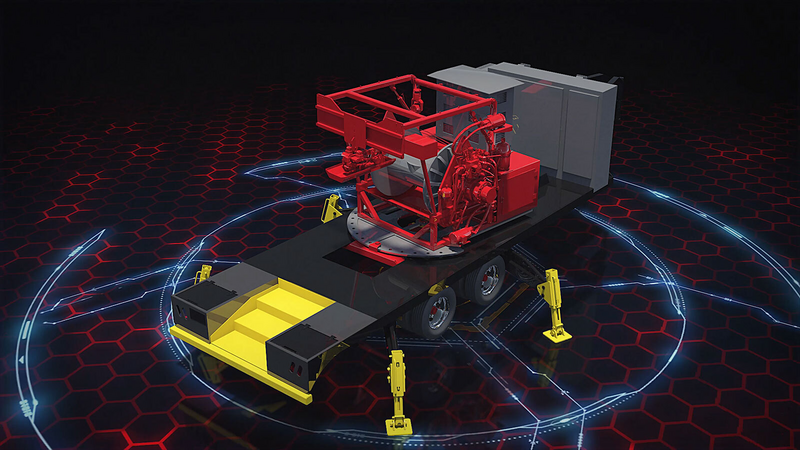

talk to an expertThe Spark Ignited Direct Drive (SIDD) pump is equipped with a reciprocating, spark-ignited engine that runs entirely on natural gas eliminating the use of diesel for hydraulic fracturing applications.

The SIDD engine is designed to be efficient and environmentally friendly, reducing emissions compared to traditional diesel or dual-fuel engines. The engine is packaged with a large transmission, power end, and fluid end resulting in a powertrain capable of delivering 3,000 horsepower (HHP).

This setup is designed to meet the high-intensity demands of hydraulic fracturing, where substantial power density is essential. SIDD competes with electric power solutions and aims to replace conventional diesel units. By using natural gas, it offers a cleaner alternative, reducing emissions, and operational costs

HHP - comparable to electric fracturing

Natural gas powered cleaner choice

Versatility, compatible with pipeline, CNG, LNG

Complexity in deployment, operations & maintenance

SIDD is designed to work in high-intensity hydraulic fracturing applications requiring high horsepower density. One of the key advantages is its ability to provide fuel savings and emissions comparable to electric systems. This makes SIDD an efficient and cost-effective choice, as it helps reduce operational expenses while maintaining high performance. The unit can be run on a wide range of gas qualities including conditioned field gas, CNG, or LNG.

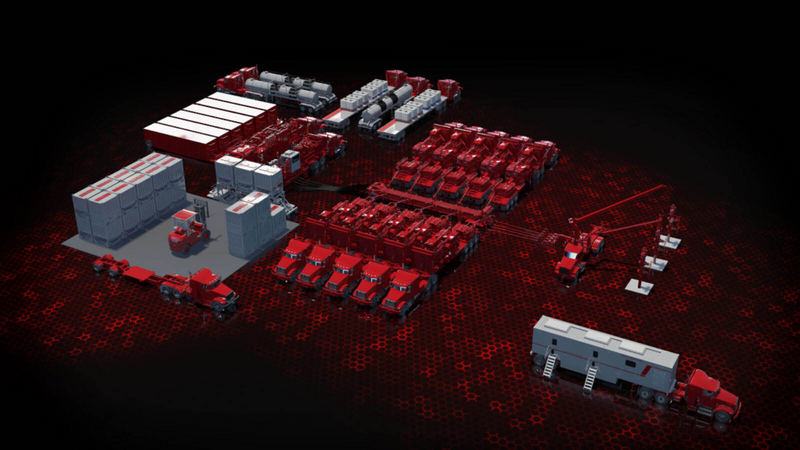

SIDD also requires a smaller location footprint by eliminating the need for separate power generation units, reducing overall operation costs, and improving efficiency. This optimization of space reduces site impact and makes it easier to deploy in various locations providing greater autonomy and reliability for operations.

One of the standout features of SIDD is that it minimizes additional crew competencies and learning curve. This means that existing personnel can operate the system without the need for extensive training or new skills, saving time and resources. Additionally, SIDD features low maintenance complexity, which helps reduce downtime and maintenance costs by using the existing supplier network.

SIDD, powered by the OCTIV® platform, offers seamless unit and spread level control. This integration enhances operational efficiency and unit health with a proactive maintenance approach. Additionally, the OCTIV platform provides customers with advanced capabilities for managing and optimizing their frac treatment.

SIDD provides significant fuel savings comparable to diesel/dual fuel systems, making it an efficient and cost-effective choice. Additionally, it offers comparable fuel cost savings as an electric fleet further enhancing its economic benefits. By using 100% natural gas, it not only reduces operational expenses but also contributes to a cleaner and more sustainable energy solution. SIDD helps use field gas effectively, maximizing resource efficiency and reducing waste.

SIDD has higher hydraulic horsepower (HHP) density, packaging 3,000 HHP in the same footprint as legacy diesel/dual fuel units, resulting in superior performance. The increased HHP density optimizes space usage and reduces site impact. This combination of power and efficiency makes SIDD an excellent choice for customers looking to optimize operations, reduce costs, and maintain high performance and sustainability.

The Halliburton ZEUS electric fracturing pumping unit delivers higher pump rates with 5,000 hydraulic horsepower.

Explore

An electric manifold with fewer failure points, faster rig-up and higher rate capacity.

Explore

An integrated system for hydration, additive, and slurry blending.

Explore

All-electric system that can be remotely operated for safety and efficiency

ExploreWorld Oil Article

In the evolving landscape of hydraulic fracturing, a transformative synergy of electrification, automation, and real-time optimization has emerged. The commingling of these technologies is paving the way for unprecedented efficiency and performance gains while reducing costs and NPT.

Read articlePodcast

Daniel Energy Partners sits down with Chesapeake Energy to talk about a recent trip to the Marcellus to visit Halliburton’s electric frac fleet. Listen in as they share key benefits of the electric fleet and stats from their first pad in Pennsylvania.

Listen Now