CleanWell® mechanical wellbore cleaning tools withstand shock force of TCP guns

Download PDFMature Fields

Deploy wellbore cleanup tools and TCP guns in a single string

Malaysia

A major operator in southeast Asia engaged Halliburton to provide wellbore cleanup in conjunction with tubing conveyed perforation (TCP). The operator required a string design that allowed perforating, deburring, cleanout, and displacement in a single trip.

Tasked to provide wellbore cleanup tools to withstand the expected shock force of the TCP guns, Halliburton was challenged to restore drift and remove debris post-perforating in a single trip with TCP. Deployment in the same string as the TCP guns required the tools to be robust enough to withstand the shock force of firing guns and provide the metallic retention necessary to collect all the produced debris.

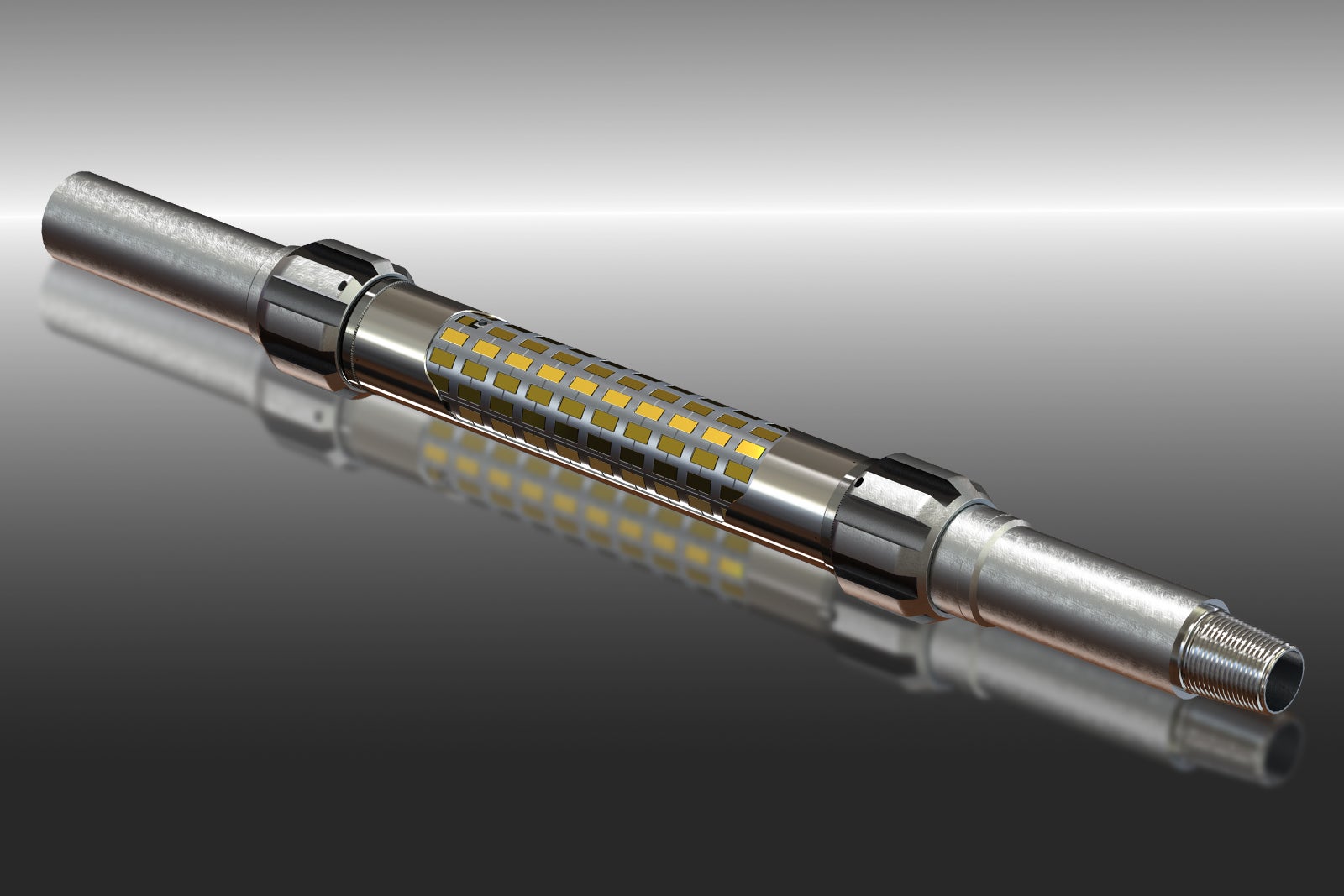

Halliburton worked with the gun supplier during the pre-job planning phase to model the expected shock forces from firing the guns on the running string. Based on a review of the simulations, Halliburton proposed using a Vali Tech® downhole filter tool, Mag Tech® casing magnet, and CleanWell® spiral wrap string mill in the string to achieve the well objectives.

The tools were spaced out in the string above the guns to ensure they remained free of damage during firing and allowed the following:

trip operation achieved objectives

lb of debris mechanically removed

hour rig time reduction

Halliburton was able to run in hole with TCP guns and successfully deburr the perforation interval, perform BHA cleanup post-perforate, and achieve displacement all in a single trip. The Mag Tech casing magnet and Vali Tech mechanical downhole filter successfully recovered 11.88 lb (5.39 kg) of metallic debris during this post-perforate deburr run. This helped prevent lost time attributed to debris-associated issues throughout the upper completion operations.

By performing this in a single run with TCP guns, the operator reduced rig time by 24 hours and eliminated the need for a dedicated cleanout run. The following objectives were met during the successful single-trip operation:

Reduce well construction costs with the latest-generation of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and optimized software modeling.