Delivered full-scale solution for cross-border CO2 transport

Download PDFCarbon capture, utilization and storage

Enabling cross-border transportation and sequestration of industrial CO2

Norway

Halliburton delivered a top-to-bottom completion solution for a cross-border CO2 transport and storage facility. Phase I of this project includes the capacity to transport, inject, and permanently store up to 1.5 million metric tons of CO2 per year. CO2 storage will be possible through one injection well, which was sidetracked and completed from the original exploration well, and a new contingency well.

With these two wells in place, the customer is motivated to drill and complete three additional injection wells to expand capacity by an additional 3.5 million metric tons to a total of 5 million metric tons annually. The expanded capacity will help the customer accelerate industrial decarbonization and provide future CO2 storage options for Europe.

The safe and successful design and operation of carbon capture and storage (CCS) wells requires careful consideration of a range of technical challenges. The primary objective is to ensure the permanent sequestration of CO2 underground, which is dependent on the integrity of the well. One challenge is helping prevent leakage of CO2 into the atmosphere, which could occur if materials used during well construction are not selected carefully. For example, the formation of carbonic acid (H2CO3) due to the mixing of dry CO2 and saline formation water can lead to corrosion of carbon steel, potentially having a negative impact on well integrity. To help prevent such issues, operators must select materials suitable for the well environment and compatible with the operator’s objectives.

Several factors were considered to help ensure the safe and permanent storage of CO2 during well construction. These included the composition of the injected CO2, anticipated reservoir pressure evolution, and well temperature variations during injection and shut-in. Additionally, the composition of formation fluids and previous knowledge gained from other CO2 injector wells were considered. Laboratory corrosion testing determined that tubular and completion equipment installed at the bottom of the well should be 25% chrome alloy or superior materials to allow a 25-year well lifetime.

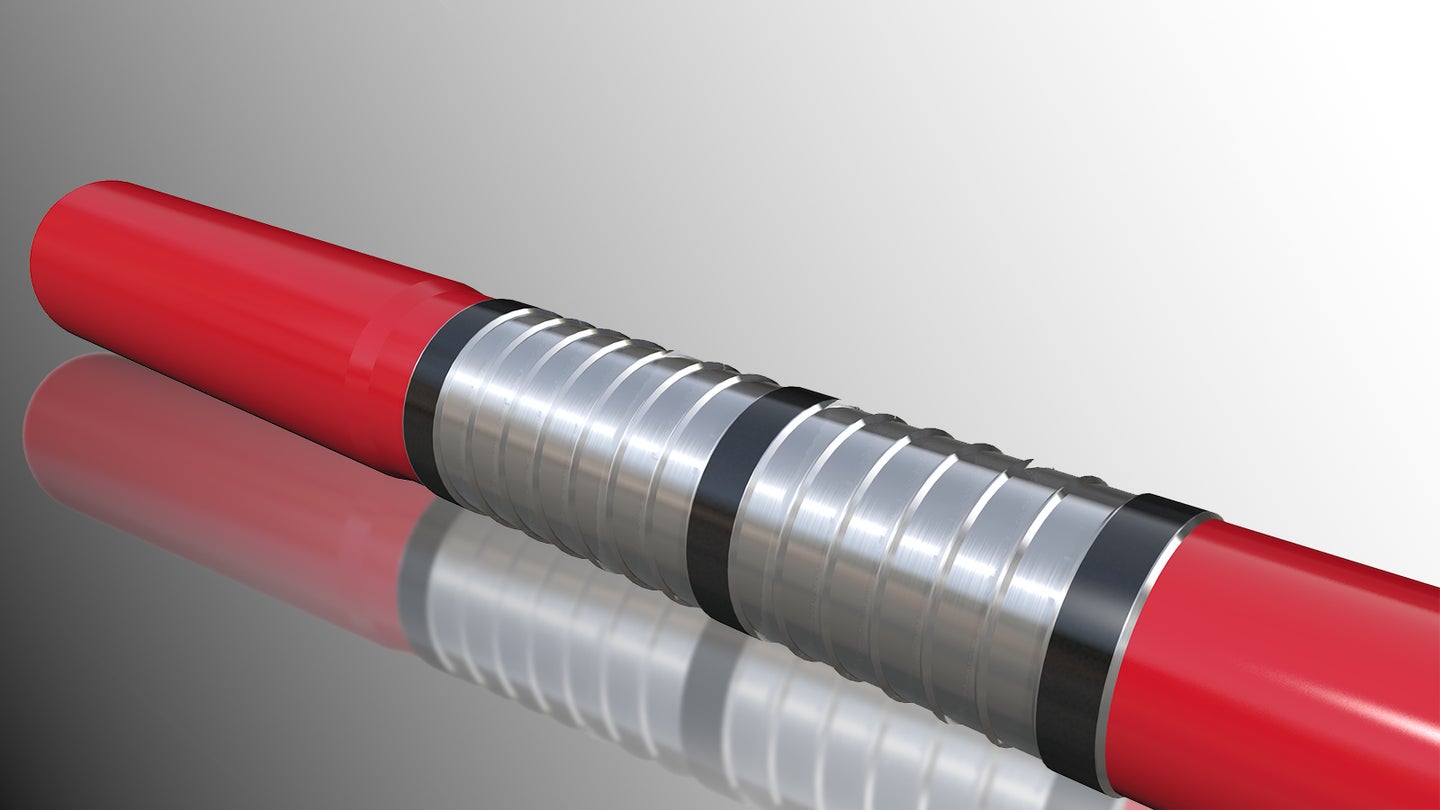

During well construction of the primary injection well, a 14-in. XtremeGrip® low equivalent circulating density (ECD) and 9 5/8-in. XtremeGrip Quick Lock liner hanger were installed, and sand control was achieved using standalone sand screens (SAS) in the openhole section. For the well's lower completion, the Halliburton Versa-Trieve® retrievable sand control packer and FS2 fluid loss control valve were used. The upper completion was finalized using the Halliburton hydrostatic-set Perma-Series® HNT packer, 4 1/2- and 7-in. Opsis® gauges, and the SP™ tubing-retrievable safety valve to ensure safety.

The contingency injector was completed similarly. A 14-in. Low ECD liner hanger was installed during well construction, and sand control was achieved by gravel packing the openhole section. A Versa-Trieve retrievable sand control packer and FS2 fluid loss control valve were used for the lower completion, and the upper completion consisted of the X-Trieve™ XHHC retrievable production packer, two 7-in. Opsis gauges, and the SP tubing-retrievable safety valve.

CCUS

Well completion solution creates the first open-source opportunity for a customer to provide safe and successful industrial transport, storage, and decarbonization as a commercial service.

Halliburton delivered a full well completion solution for the open-source offshore commercial cross-border CO2 transport and storage demonstration project, which will accelerate industrial decarbonization and provide future CO2 storage options for Europe.

Once Phase I of the project is completed, the operator will have the capacity to capture and store 1.5 million metric tons of liquid CO2 annually. Based on customer demand, the operator can drill and complete additional wells to increase the storage volume annually.

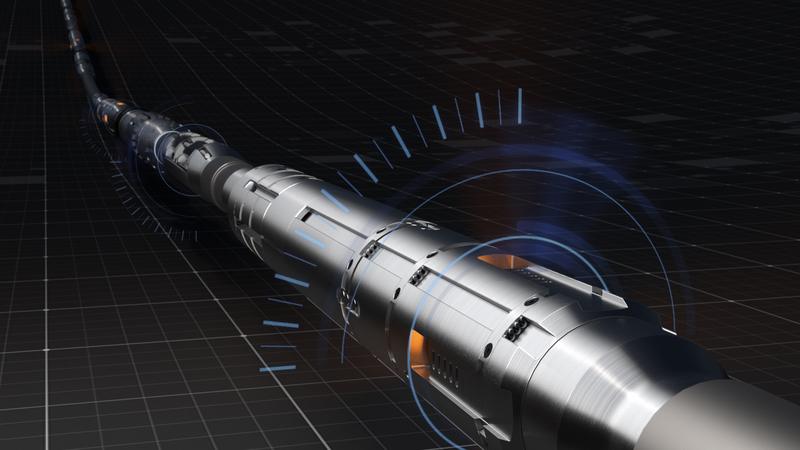

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.