Cement through TRSV solutions is successful in Gulf of Thailand for more than five years

Download PDFMature Fields

Clean fluid displacement

Gulf of Thailand

To ensure TRSV functionality for cement through applications, the key focus areas during installation are:

Multifaceted solution to cement through TRSV:

More than five years of successful cement operations through TRSVs with zero NPT related to valve failure

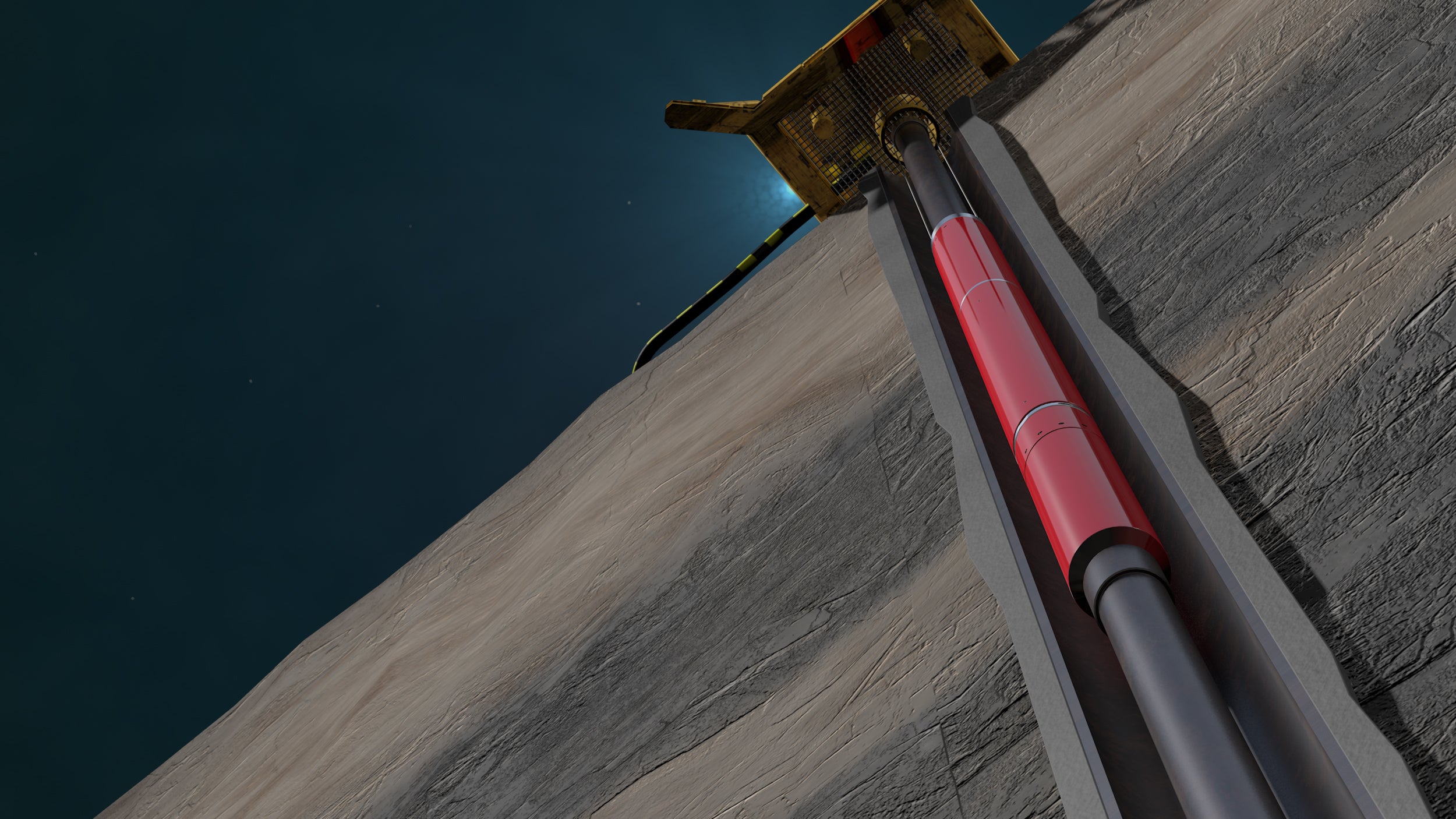

The elimination of production casing and cementing a monobore completion tubing string in place as the main production conduit is a common completion methodology for the economic development of fields with short well life. This method effectively replaces the production casing with a completion string that is run into the drilled openhole section and cemented in place, which is referred to as a “cement through” application. This reduces rig time and costs by eliminating a standard liner and subsequent wellbore cleanup operations. It also eliminates liner hangers, production packers, and other completion accessories. However, installing a tubing retrievable safety valve (TRSV) is still necessary for many of these “cement through” completion designs.

The safety valve might not function as designed after the cement application if cement debris becomes trapped in the valve components and compromises flow tube movement (or the valve’s capability to seal). The TRSV design and operational practices during cement operations are critical to ensure the valve functions properly after the cement operation.

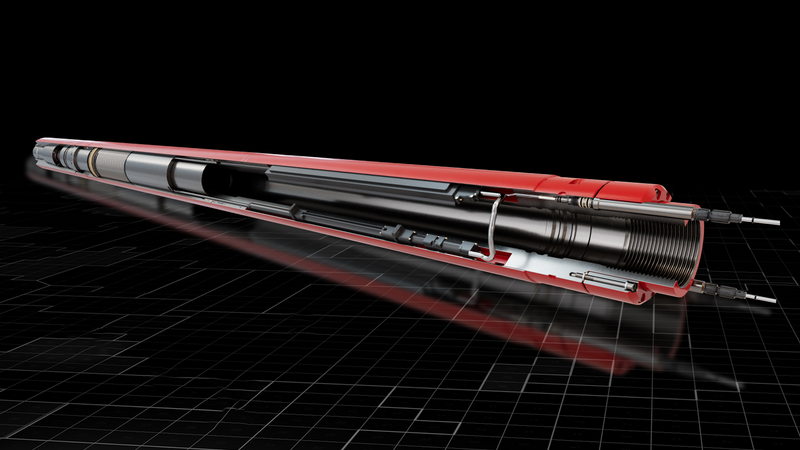

Halliburton developed a solution to address these challenges through a combination of valve design features, the addition of a manufacturing specification for “cement through” applications, and adherence to a “cement through” valve operational procedure.

Valve design features include the metal-to-metal (MTM) seating of the opening prong to the lower shoulder of the bottom sealbore, which helps keep the flapper and critical components isolated. This prevents cement accumulation during cement operations. In addition, inverted flow tube designs and a wiper ring with cleanout ports help clear potential cement debris during valve cycling.

Based on more than 20 years of experience with “cement through valve” installations, Halliburton developed operational procedures to help reduce the risk associated with “cement through TRSV” installations. These procedures eliminate downtime and help ensure long-term valve function.

“cement through TRSV” installations performed worldwide

of experience with “cement through valve” installations

NPT

Halliburton delivered engineered completion solutions and technical expertise to an operator in the Gulf of Thailand during “cement through TRSV” installations from 2016 to 2021. This resulted in the successful installation of more than 330 valves with zero NPT related to equipment failure.

By providing engineered completion solutions with distinctive service quality, Halliburton has performed more than 3,200 “cement through TRSV” installations worldwide to maximize operator asset value.

World’s first electric tubing-retrievable safety valve, enabling a fully electric completion system with zero risk of exposing electronics to wellbore fluid.