First operation in Egypt with IsoBond™ cement solution improves CBL results in permeable sands formation with gas influx

Download PDFMature Fields

Losses induced by high pump pressure

Egypt

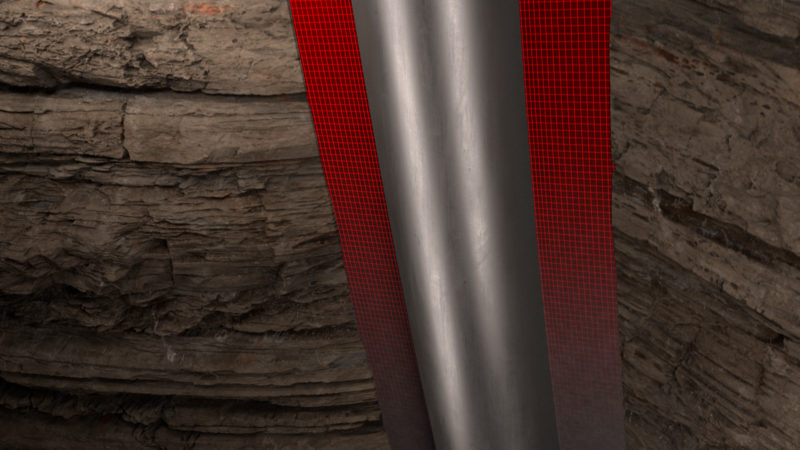

Drilling operators face increasingly challenging environments to unlock potential reservoirs in the search for hydrocarbon. Gas influx and cement debonding are regularly encountered in formations characterized by highly permeable sands. This creates channels in the cement sheath that can lead to communication between water zones in addition to potential remedial cement operations to help isolate them.

The operator encountered losses attributed to cement fallback caused by high pump pressure and the presence of gas pockets within the cement sheath. Interconnected channels in the well increased water cut during production and a cement bond log (CBL) revealed cement debonding across the highly permeable sands of this formation.

Halliburton recommended implementing a tailored IsoBond™ cement solution to mitigate flow through the unset cement and improve barrier dependability. The system provided tight fluid-loss control at 15 cc/30 minutes to minimize the loss of slurry filtrate across the highly permeable sands. This was in addition to rapid gel strength development with a two-minute transition time to help mitigate the potential for flow through the unset cement.

This cement system improves barrier dependability through reduced cement sheath permeability and increased shear bond strength. The slurry provides lower rheological readings and improved cement mixability, which helps decrease friction pressure while pumping.

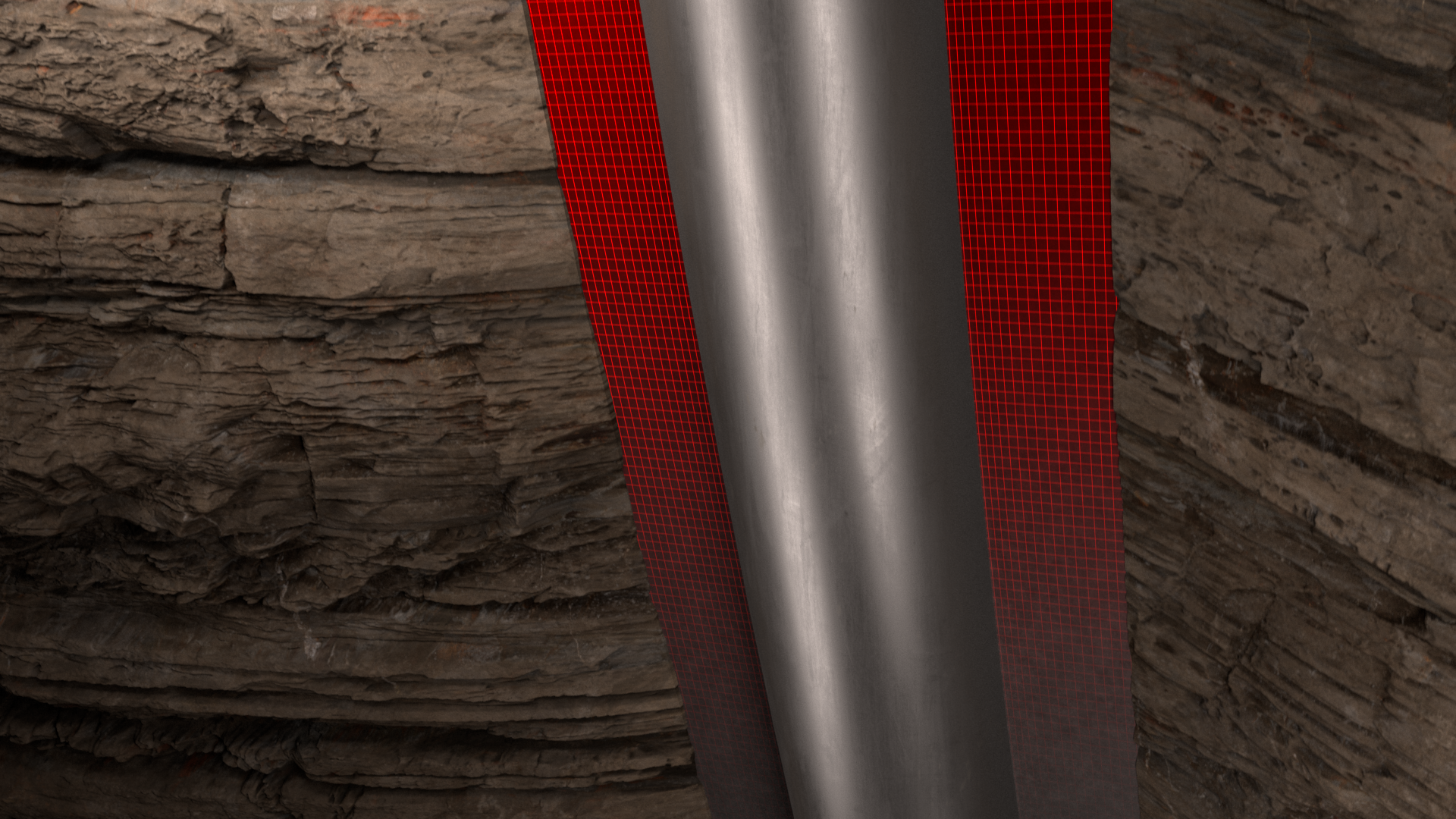

Implementation of IsoBond™ cement system in Egypt

psi decrease in pump pressure after deployment

Losses during operation

This was the first implementation of the IsoBond cement solution in Egypt. Pump pressure throughout the operation decreased by approximately 500 psi. Additionally, no losses were reported during the operation. The CBL showed no signs of cement debonding and did not record gas traces in the cement sheath.

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.