Successful installation of seven-zone advanced intelligent completion using SmartPlex® II control system

Download PDFMature Fields

Remote and surface-controlled completion design

Middle East

In the mature field environment, the race to increase ultimate oil recovery and tap into every reservoir zone is relentless. Maximizing one platform slot to access as many reservoir zones as possible is essential to overall project economics. Specific features, such as remote, real-time reservoir monitoring and selective zonal control capabilities, are essential to production optimization and efficient reservoir management, without the need for costly well intervention.

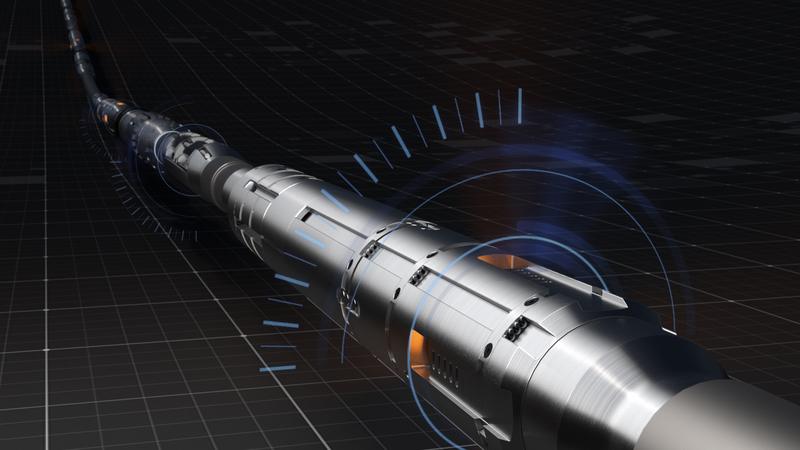

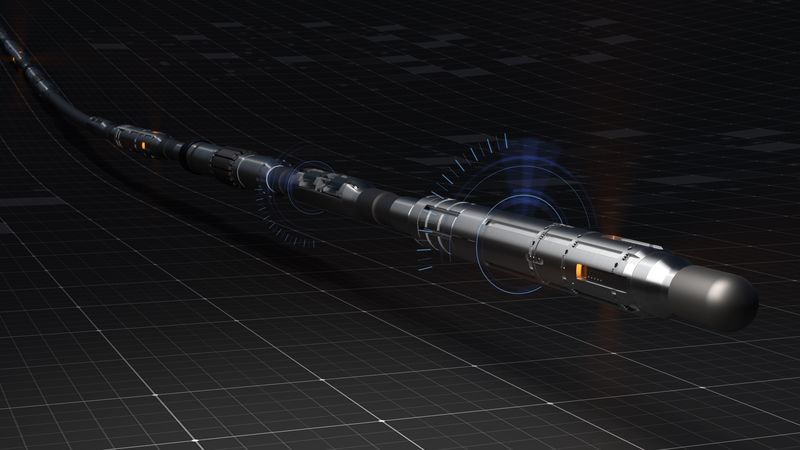

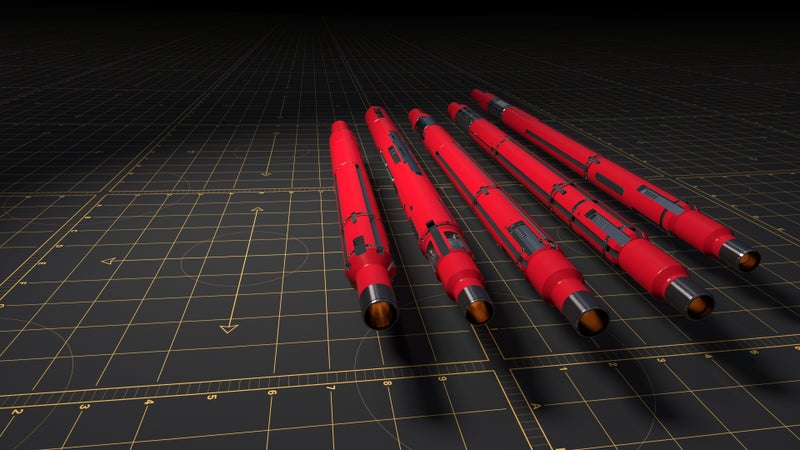

Using one of the most advanced intelligent completion designs to date, Halliburton successfully installed a seven-zone electro-hydraulic SmartPlex® II HS interval control valve (ICV) flow control system combined with a full DataSphere® permanent downhole gauge system (13 Opsis® gauges 150°F/10 kpsi). The advanced downhole completion integrated with a surface digital infrastructure system allows real-time surveillance of downhole data. It provides the well unprecedented reservoir contact with full zonal optimization through remotely controlled HS-ICV choking capabilities.

Halliburton tailored a complete electro-hydraulic seven-zone intelligent system for the operator. It included the latest SmartPlex® II electro-hydraulic control system mounted on three HS-ICV variants (a 2 7/8-in. shrouded ICV with 3 1/2- and 4 1/2-in. unshrouded ICVs) using a flow trim design to meet the specific reservoir and production characteristics. The electro-hydraulic system eliminates the need for additional tubing hanger penetrations, which enables up to a 12-zone completion using only three penetrations.

The SmartPlex II downhole control system uses two hydraulic and one tri-wire electric line from the surface to selectively actuate multiple downhole ICVs. Finally, the downhole design was tied into the Halliburton digital infrastructure surface control and monitoring system. This system allows the operator to collect, monitor, and transmit permanent downhole gauge (PDG) data for analysis and control downhole ICVs from the surface. Additionally, the digital infrastructure allows operators to remotely configure/position ICVs and interpret and model data acquired by the system from a shore-based office desk.

Zone electro-hydraulic completion successfully deployed

Day ahead of schedule

Opsis® guages installed with live monitoring

The project was delivered safely on time and per the operator’s design and expectations, and all equipment worked as designed. Workshop preparation required an impressive 50 days to fully prepare the subassemblies, which included the makeup of 150+ hydraulic FMJ connectors and 60+ electrical terminations. Offshore installation was completed in less than 10 days, which involved installation of the lower and upper completions, and was completed one day ahead of schedule. Once the well was completed and all surface lines were tied in, it was successfully commissioned for production.

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Collect, transmit, and analyze downhole data, and remotely control and monitor reservoir zones with Halliburton SmartWell® completion systems.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.