MatchSet® liner hanger system integrated with wet shoe sub (WWS) contributes to successful completion of four wells

Download PDFMature Fields

Operator required a liner solution for a cemented refrac liner run on tubing

North Dakota

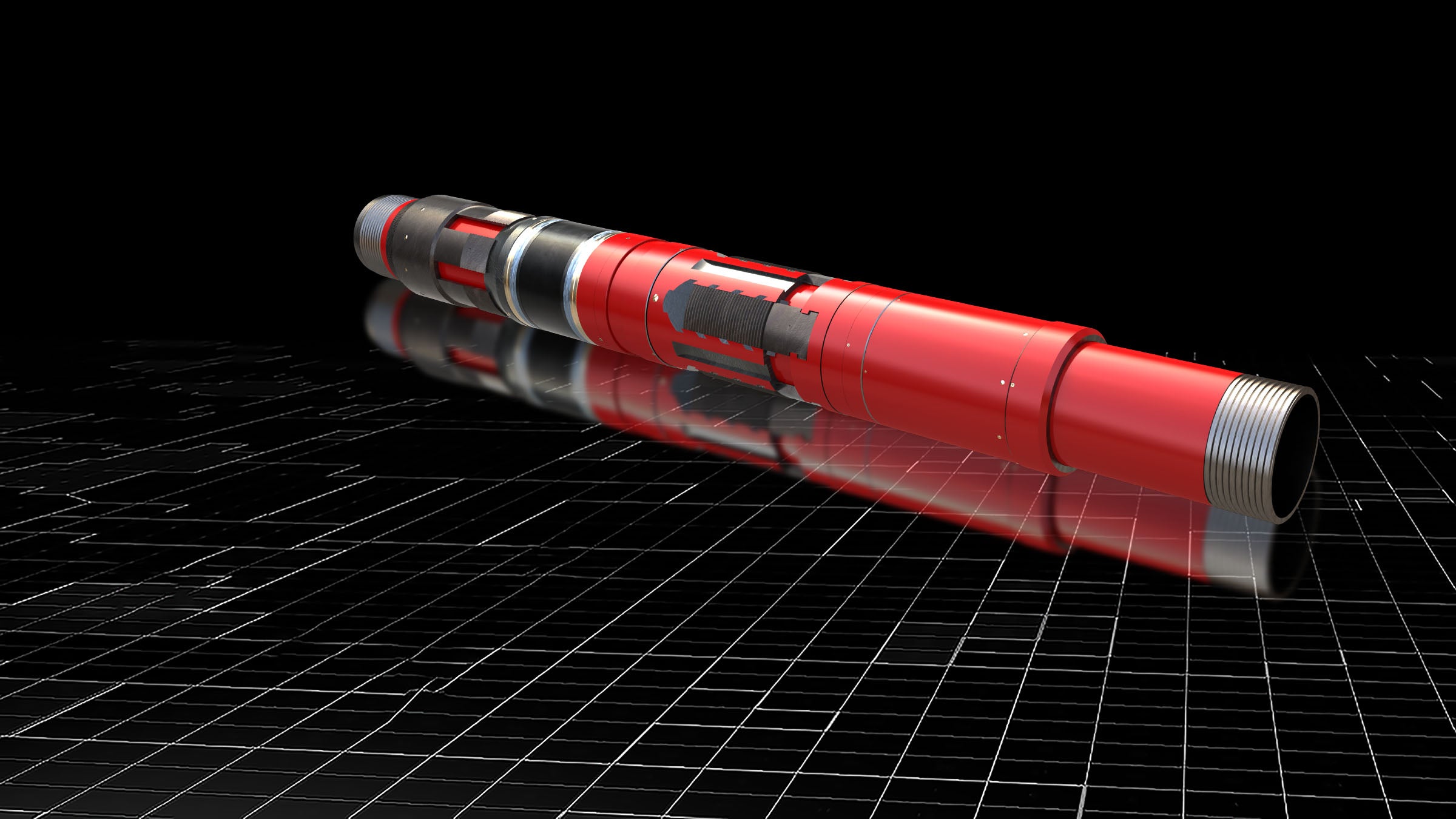

MatchSet® conventional liner hanger system

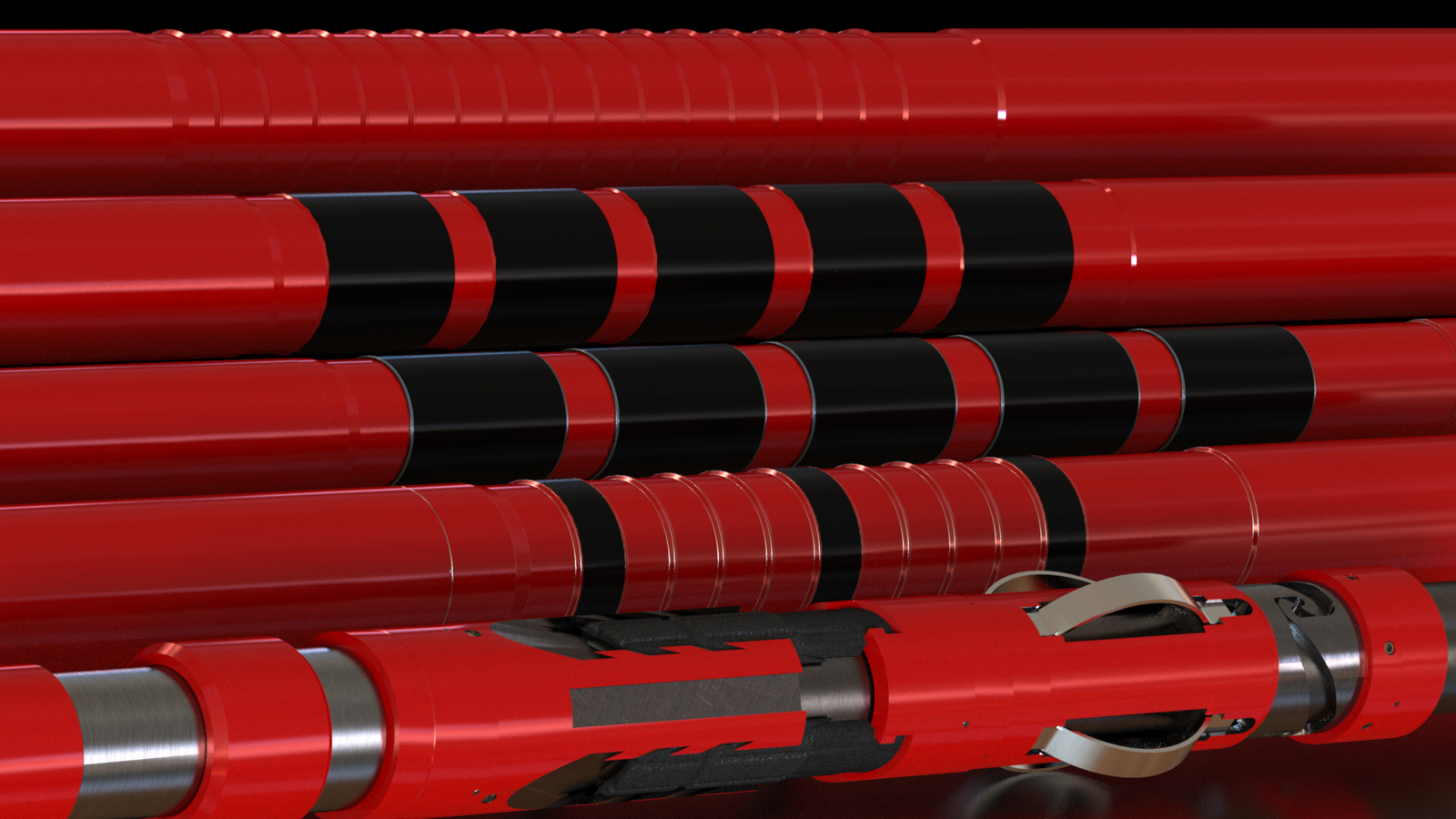

Wet shoe sub

An operator in North Dakota required 3.5-in. liner installed and cemented inside an existing 4.5-in. production liner to prepare for a four-well refracturing and stimulation project. The intermediate casing needed to be isolated from pressure up to 9,500 psi for stimulation. Halliburton recommended the modular MatchSet® liner hanger system for its configurability and conventional liner hanger capabilities

The liner installations, deployed on a service rig with tubing, posed limitations compared to running liner with drillpipe on a drilling rig. Maximizing the ID of the liner results in small annular clearance and potentially higher equivalent circulating densities (ECDs) during cement operations. A short shoe track was necessary to reduce the distance from the current plug-back depth to the first stage of the fracture, which increased pay length. All wells exhibited low pressure and were unable to support a full column of fresh water. With unknown fluid levels, activation of pressure-operated tools was identified as a challenge.

Halliburton developed a new 3.5-in. wet shoe sub to create a flow path from inside the newly installed liner, through the bottommost sleeve or perforations in the existing completion, to the formation. The 3.5-in. WSS is a compact 3-in-1 tool with a shearable ball seat used for liner hanger operations, a landing collar for a wiper dart, and a wet shoe feature. All liner hanger equipment operates on differential pressure and maintains a designed sequence of shear events during liner hanger setting operations, even with unknown fluid levels. The compact design enabled maximized pay length through a reduced shoe track length.

The conventional liner hanger system completed all pressure events to set the liner hanger and release the running tool before cement was pumped, allowing elevated pump pressure during cement operations, if necessary. The deployment on a tubing workstring was accommodated using a custom running tool configuration and provided the capability to isolate the annulus above the liner top from the liner below and pressure test post-circulation of excess cement.

psi required for stimulation

in. WSS developed for project

wells successfully completed

Equipment selection from the compact WSS to the MatchSet liner hanger system enabled the installation of a liner system with the requested capabilities and verified integrity. Halliburton and the operator collaborated to complete all four wells and equip the operator with a liner ready for future stimulation operations.

Frac Sleeve Systems

The Halliburton wet shoe sub, a valuable asset in the Toe of Well Solutions inventory, is a tool engineered to help ensure cement displacement and provide casing integrity testing and injection into the first zone.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.