IsoBond™ cement system enables excellent cement bond log results during 4 1/2-in. frac string operation

Download PDFUnconventionals

Achieve proper zonal isolation for challenging 4 1/2-in. frac string operation

UAE

The increased demand for energy worldwide drives operators to seek innovative methods for hydrocarbon production. Unconventional extraction is a widely used method that involves hydraulic fracturing to unlock the vast potential for unconventional oil resources. Proper zonal isolation is imperative when fracturing operations are performed through a cemented string to achieve optimum results and maximize oil extraction.

An operator in the Middle East, ADNOC, faced several issues in the past attributed to poor zonal isolation for most of the frac strings cemented in an unconventional field. This led to zonal communication while fracturing, changes to the fracturing programs, and overall loss of production, which increased costs. The systems used to cement these frac strings were limited to mechanically enhanced systems with post-expansion properties, which did not achieve satisfying cement bond log (CBL) results.

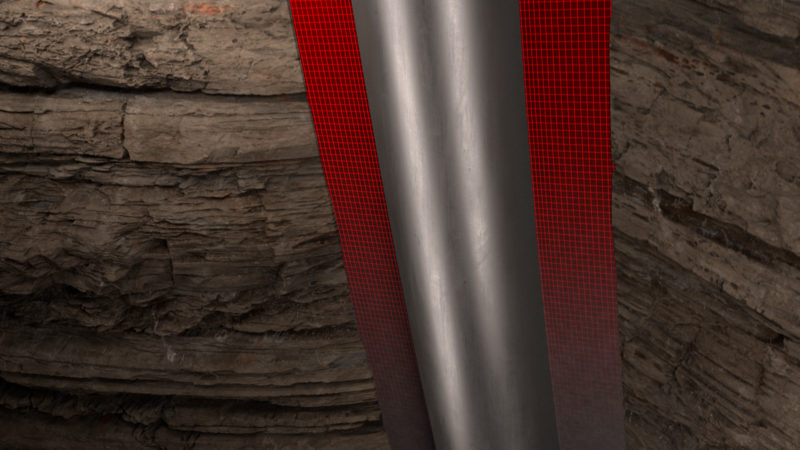

Halliburton supported the operator in identifying the cause of repetitive poor CBLs. As a result, Halliburton proposed the IsoBond™ cement system to minimize fluid loss to the formation. The IsoBond cement system provides tight fluid-loss control to help ensure successful cement slurry placement across challenging formations.

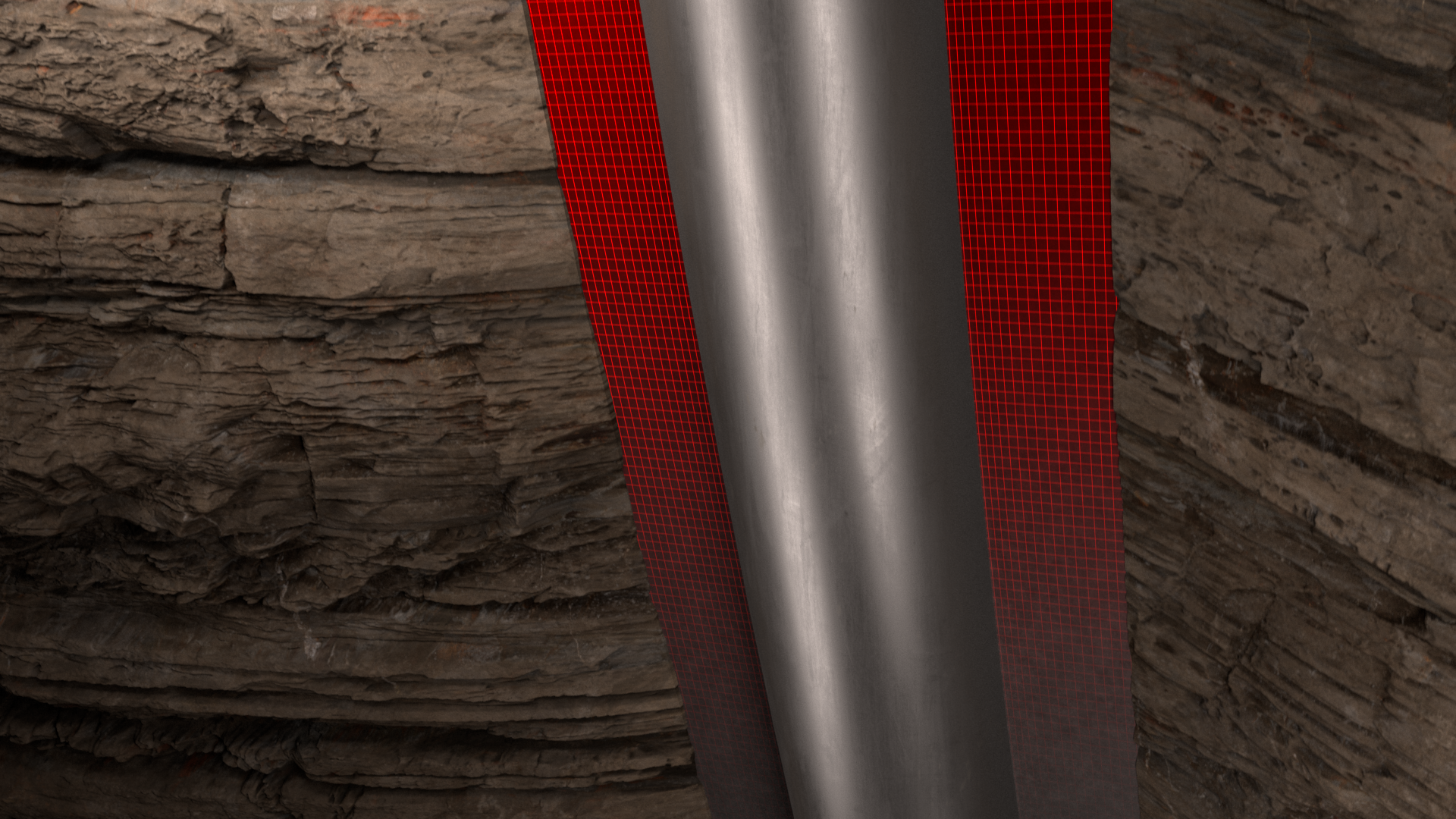

The system builds rapid gel strength, and this short transition time reduces the risk of gas or fluid flow through the cement slurry. The increased anchoring capability of the system supports zonal isolation and prevents debonding that can create a flow path for fluid or gas migration up the annulus. To further ensure proper bonding around the pipe, the system was designed with a preset expansion material to overcome cement shrinkage during the cement setting stage.

Halliburton supplemented Tuned® Defense™ cement spacer with BridgeMaker™ II lost-circulation material (LCM) and pumped it downhole ahead of the IsoBond cement system. Tuned Defense cement spacer is designed to optimize fluid rheology, mitigate losses, improve mud displacement, and prepare the wellbore for cement. BridgeMaker II LCM enhanced the cement spacer to help prevent losses and achieve the desired top of cement (TOC).

Losses during cement placement

Confirmed good cement bonding

Operational objectives met

This operation resulted in the flawless execution of the first IsoBond cement system application in the Middle East region by ADNOC. It was used for a challenging 4 1/2-in. frac string placed in an 8 1/2-in. openhole with more than 3,000 ft of lateral section. All operational objectives were met with no losses during cement placement. Excellent CBL results were achieved with good cement bonding across the zones to be fractured. After the successful execution and evaluation of the first IsoBond™ cement system by ADNOC, the operator decided to standardize IsoBond cement system applications across all challenging frac string/liner operations.

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Improves cement spacer designs to prevent lost circulation.