Innovative solution saves 16 hours of rig time on average for each of operator’s first five wells

Download PDFDeep Water

Reduce mlt installation time compared to previous mlt campaign

North West Shelf

An operator developing a deepwater field off the North West Shelf of Western Australia required a minimal subsea infrastructure with tight lateral spacing in an environmentally sensitive area. In this operator’s second multilateral well development campaign with Halliburton, 17 laterals were planned from seven wells targeting a sandstone reservoir. To manage production, these laterals were to be completed with sand screens and inflow control devices. Halliburton recommended a simplified installation process, using the FlexRite® isolated tieback multilateral system with an innovative all-aluminum window joint, in order to reduce well construction time. The well architecture was also advanced from a dual-lateral plan to a trilateral plan. As a result, the operator was able to achieve an estimated reduction of 90 days in rig time for this field development, for an estimated overall cost savings of $90 million, compared to a single-lateral development scenario.

To reduce deepwater development costs for a new field, an operator off the North West Shelf of Western Australia challenged Halliburton to reduce the project’s well construction time as compared to the previous multilateral campaign. Eliminating steel milling debris was also a concern, as this debris requires pulling BOPs after milling the window, which is a costly and time-consuming operation in an offshore environment. Additionally, the operator required a minimal subsea infrastructure footprint with tight lateral spacing to achieve optimal operations in an environmentally sensitive area.

In previous operations, to ensure that the window exit was high side, the pre-milled window joint required orientation downhole. Therefore, the casing string required rotation to the desired orientation once on bottom, prior to cementing. Typically, window orientation would be pulsed to surface via a measurement-while-drilling (MWD) tool run on an inner string inside the casing. Streamlining these steps would increase efficiency of the operation and further reduce costs.

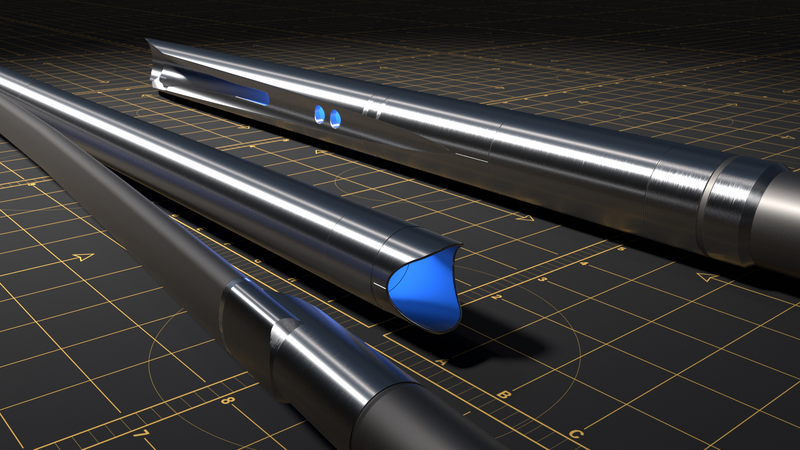

To improve on installation time for this project, Halliburton developed an all-aluminum window joint for use with the FlexRite multilateral system, which provides high-strength, hydraulically isolated TAML Level 5 junctions with sand control. This system also maximizes cross-sectional flow area and load carrying capability, and allows intervention and lateral re-entry.

The innovative new joint no longer incorporates a pre-milled steel window, allowing it to be milled out of high side without needing to be oriented. Additionally, milling of the aluminum window would produce only aluminum cuttings and no steel swarf, thus eliminating the need to pull blowout preventers (BOPs) and facilitating easy debris management. The window joint can be made up to the 9 5/8-in. casing string, run in hole, and cemented as per normal casing operations. MWD on an inner string and casing rotation are no longer required, resulting in significant reduction in equipment requirements and multilateral installation time.

In addition, the FlexRite system was instrumental in advancing the operator’s well architecture from dual-lateral to trilateral because the system is fully stackable, allowing for well designs with two or more laterals, thus reducing the project’s environmental impact and incremental lateral construction costs.

five wells

average rig time saved

million estimated saved

In this environmentally sensitive application, the FlexRite multilateral system and all-aluminum window joint technology reduced the rig time recorded in previous installations while also enabling advanced drainage architecture to be constructed with minimal subsurface infrastructure.

In this environmentally sensitive application, the FlexRite multilateral system and all-aluminum window joint technology reduced the rig time recorded in previous installations while also enabling advanced drainage architecture to be constructed with minimal subsurface infrastructure. The FlexRite system was successfully installed in three dual-lateral and two trilateral wells (the first trilateral wells for Halliburton in Australia), all TAML Level 5. For these initial five wells, the new, simplified installation process of the all-aluminum window saved the customer an additional 16 hours per well (saving a total of approximately $3.3 million on these five wells) over previous installation times.

In addition, the operator’s well architecture was advanced from the dual-lateral wells of the previous campaign to trilateral wells for the new campaign, which will further reduce development costs of the new field. The reduced rig time for these first five wells in this multilateral field development indicates that the FlexRite system will enable the operator to achieve an estimated reduction of 90 days in rig time for this field development (for an estimated overall cost savings of $90 million), compared to a single-lateral development scenario.

FlexRite® MIC System

Meritorious Award for Engineering Innovation Exploration and Production E&P Magazine (2014)

Download Data Sheet

FlexRite® System

The FlexRite® system includes a host of variants, extending its capabilities into intelligent completions, long lateral liner deployments and existing well re-entry applications.

Download MLT catalog

The Halliburton FlexRite multilateral system is robust, versatile, and configurable for TAML Level 5 pressure sealed junctions