Electrification enables the future of completions

Download PDFMature Fields

Provide long-term downhole electronics reliability

Global / Netherlands

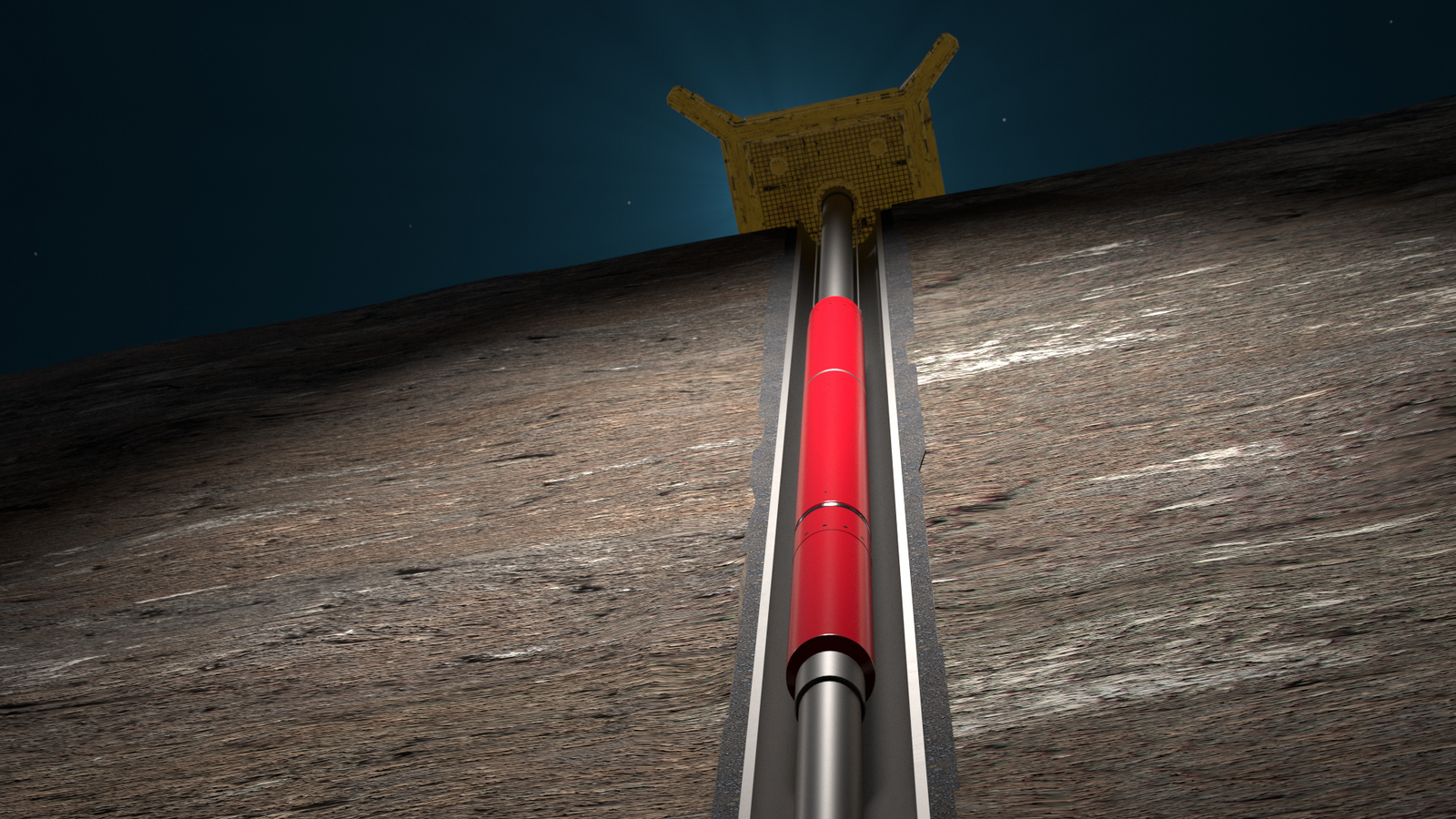

Significant advancements in reliability and functionality have marked the evolution of tubing-retrievable safety valves (TRSVs). Since their early development, these critical well-completion components have undergone numerous innovations to enhance performance and safeguard oilfield operations. Halliburton’s latest innovation, the all-electric EcoStar® electric tubing-retrievable safety valve (eTRSV), is designed to meet the demands of modern oilfields and provide superior reliability and operational efficiency. This new product represents a leap forward in TRSV technology to provide a safer and more efficient future for the oil and gas industry.

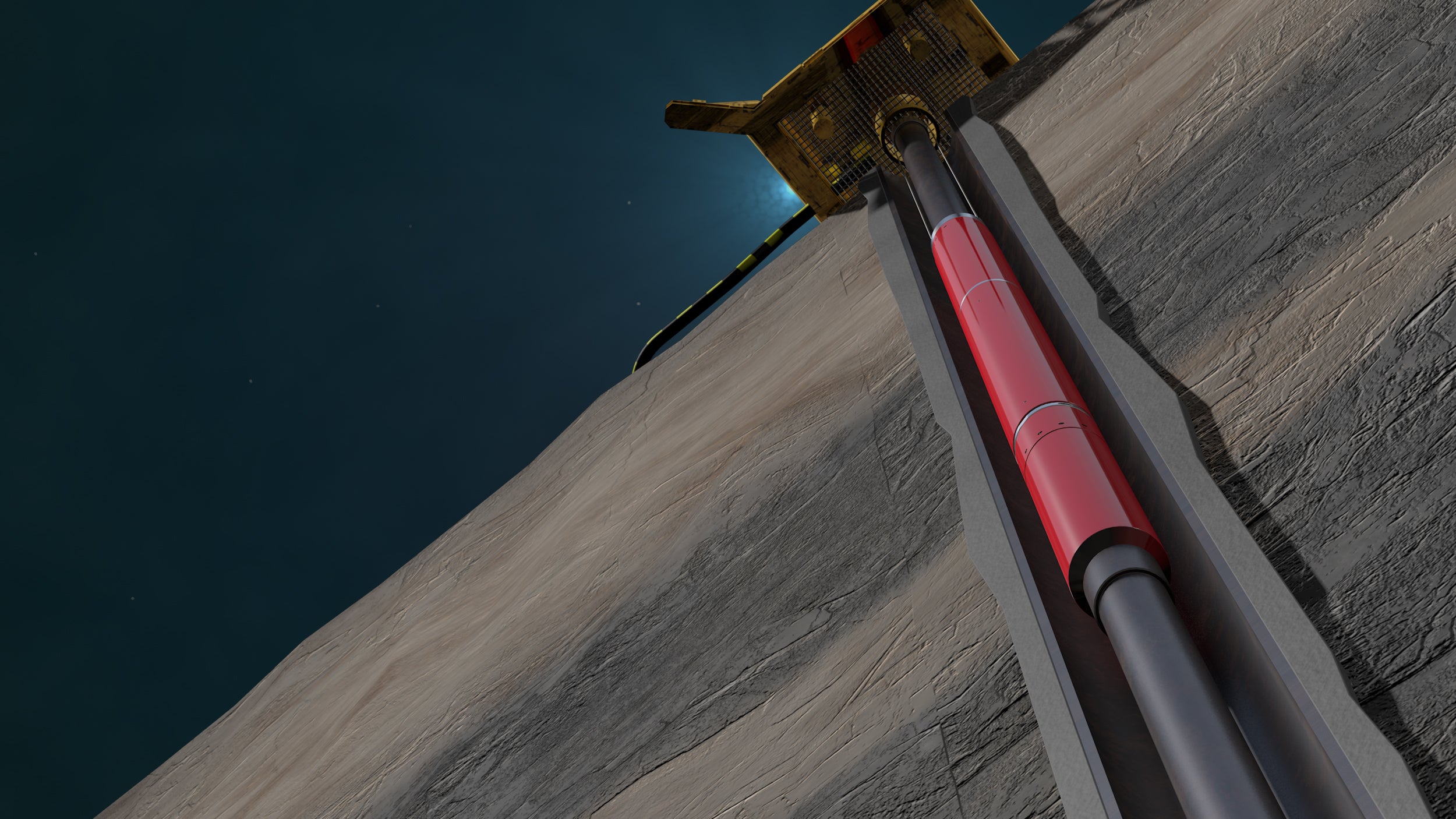

For years, the industry has sought an electric surface-controlled subsurface safety valve with low power requirements to eliminate the need for hydraulics. Hydraulic systems in subsea wells are associated with high costs and potential health, safety, and environmental (HSE) risks. Subsea hydraulic systems are often complex, difficult to install, and expensive. Hydraulic fluid release and high-pressure surface equipment can be hazardous to personnel and the environment. The complex nature of subsea hydraulic systems can result in reliability challenges and slow hydraulic cycle times, which can cause production deferrals.

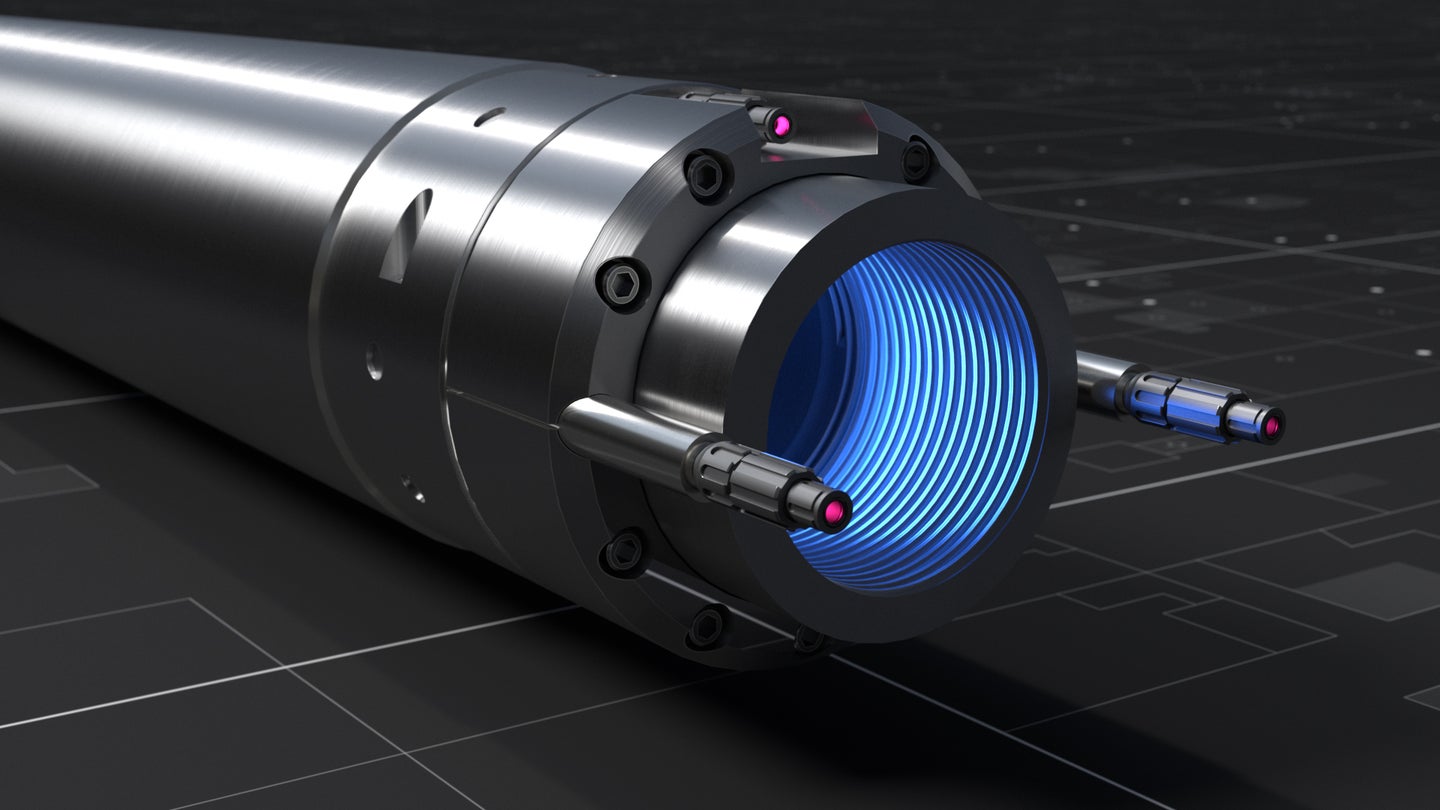

Halliburton’s all-electric safety valve is an advancement in safety valve technology, enabling the removal of the hydraulics system. A first-generation 5 1/2-in. EcoStar® eTRSV was installed in 2016 and was the first eTRSV to meet these requirements—and thus solve the 30-year challenge of hydraulic actuation removal. The EcoStar eTRSV design combines magnetic coupling technology with a fully redundant electric actuation system. This design increases reliability through complete isolation of the actuation system from well fluid and pressure and enables real-time valve monitoring to improve safety and operational efficiency.

depth limitations for all-electric actuation

risk of electronics exposure to produced wellbore fluid

actuator reliability in this case study

The 5 1/2-in. EcoStar eTRSV installed in this case operated flawlessly with 100% actuator reliability and remained fully functional throughout the life of the well.

A second-generation EcoStar eTRSV design is now available to replace hydraulic subsea control systems with electric systems. This eliminates personnel exposure to high-pressure hydraulic control systems and reduces the risk of hydraulic fluid release into the environment. Compared to hydraulic systems, electric technology helps increase reliability, offers less complex subsea distribution, and has simpler hardware components.

The EcoStar eTRSV is a key component that enables the electrification of completion systems to reduce CAPEX, OPEX, and HSE risk. It provides all-electric actuation and allows redundant actuation and control systems.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.