Operator achieves record ROP of 267 ft/hr, drilling 2,336 ft with motor BHA

Download PDFUnconventionals

Improve ROP for an unconventional vertical deep gas application

Vertical deep gas application

An operator approached Halliburton to engineer a bit for an unconventional, vertical deep gas application. The operator had been experiencing low rates of penetration (ROP) with previous bit configurations and sought improved performance and rerunnability.

Halliburton conducted a comprehensive application study and employed the Design at the Customer Interface (DatCI™) process. Within this process, Application Design Evaluation (ADE™) specialists collaborated with the customer to define specific bit solutions.

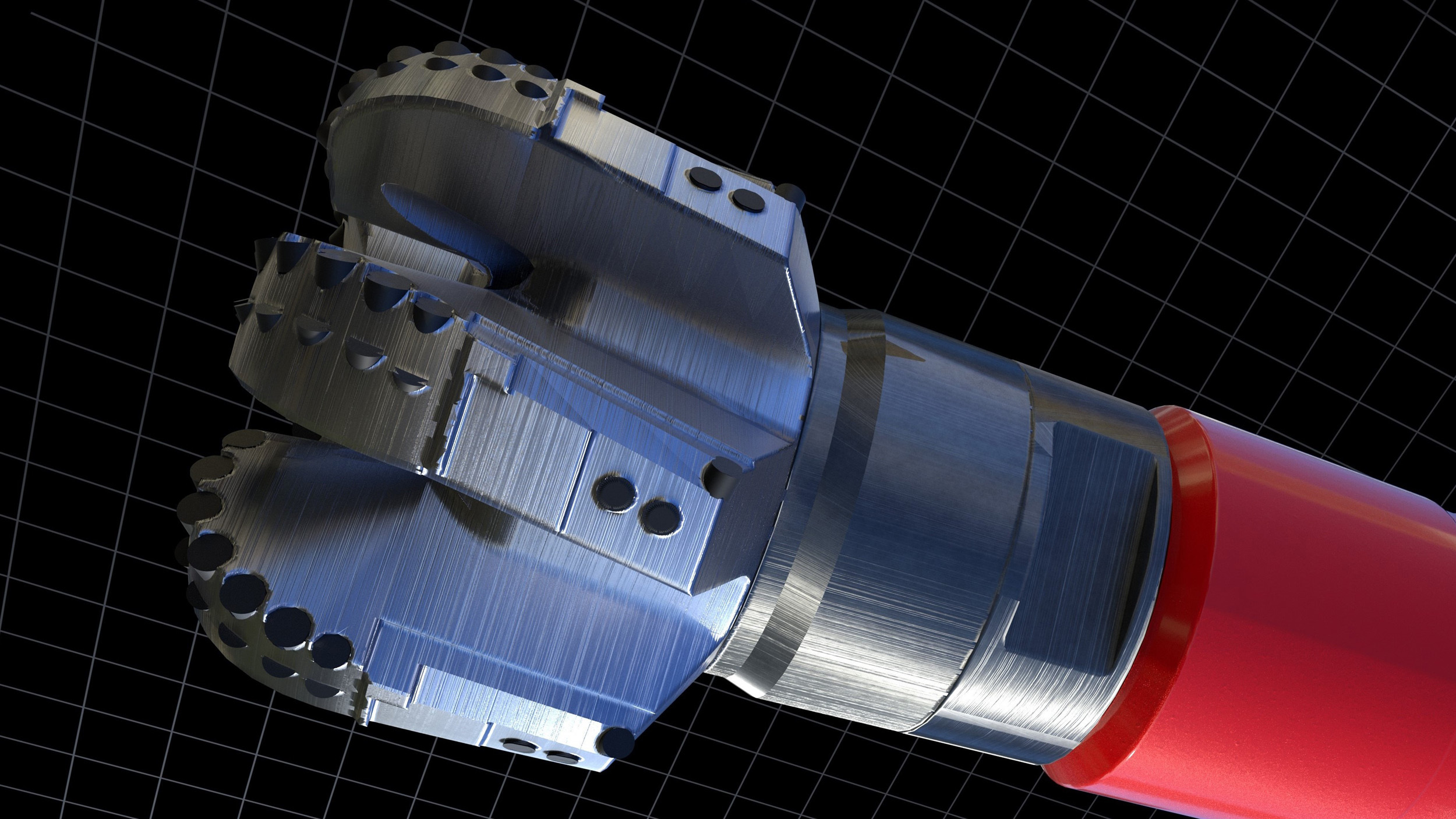

The chosen solution was the Hedron® fixed cutter drill bit. To optimize efficiency, enhance performance, and reduce cost per foot (CPF), the ADE specialist made several adjustments:

The Hedron drill bit successfully drilled 2,336 ft using a motor BHA. It achieved an impressive ROP of 267 ft per hour, which was the highest in the field at the time. This performance represented an approximately 15% improvement over the previous field record. When they pulled the bit in rerun condition, it demonstrated its reliability. Additionally, the reduced section drill time resulted in cost savings for the operator.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.