IsoBond™cement system provides enhanced dependability and long-term isolation to mitigate fugitive emissions

Download PDFMature Fields

Stringent zonal-isolation standard in a highly permeable formation

Iraq

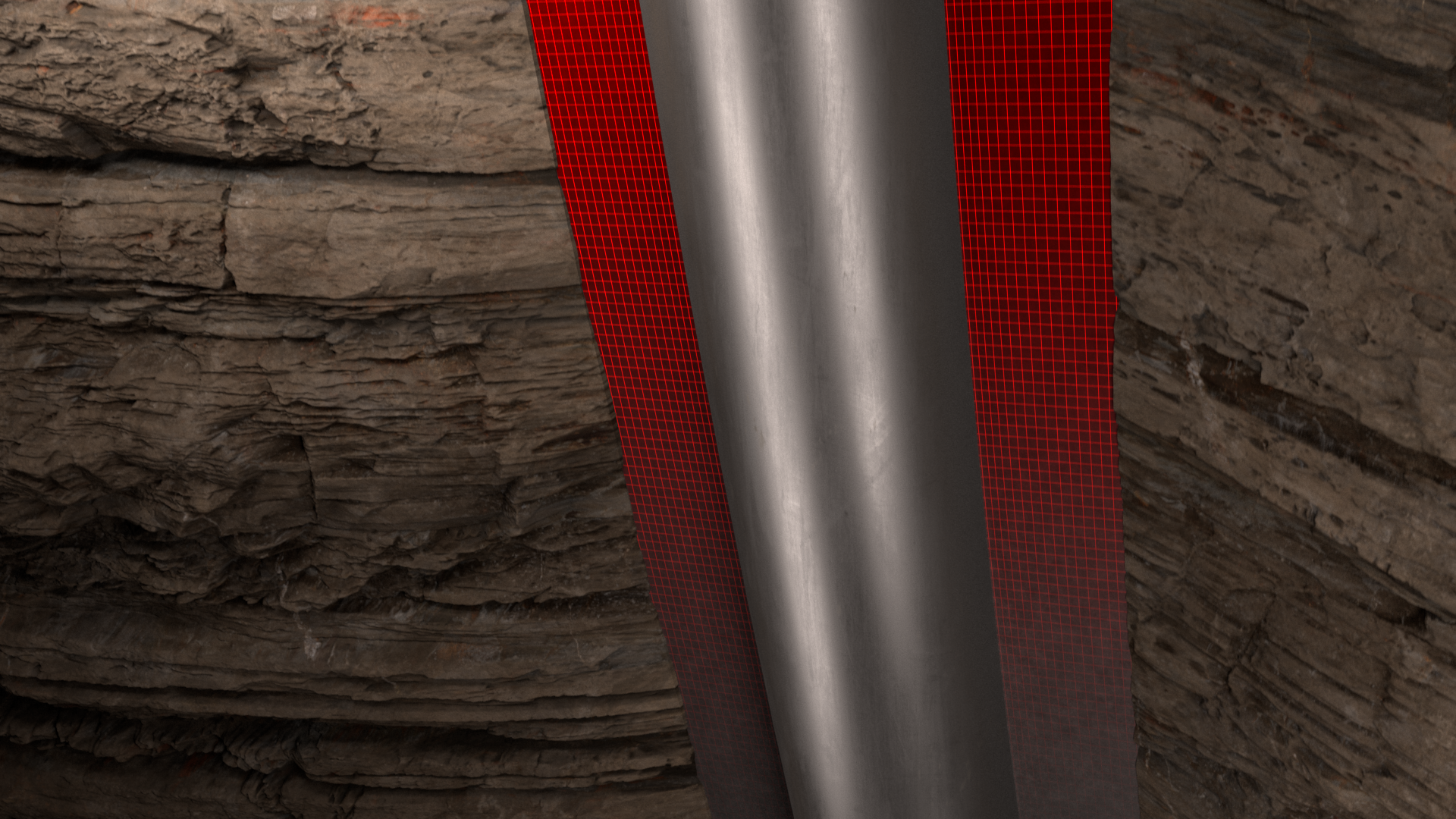

An oil field in southern Iraq presents distinct challenges to achieving the minimum standard of zonal isolation. Highly permeable formations and depleted reservoirs make appropriate well barrier selection crucial to isolating potential flow zones and maintaining well integrity throughout the life cycle.

An operator established stringent criteria to meet the field’s zonal isolation requirements, which included:

However, because of the permeable rock characteristics and depleted reservoirs, seepage losses and higher differential pressure led to increased fluid loss from the cement slurry and compromised zonal isolation.

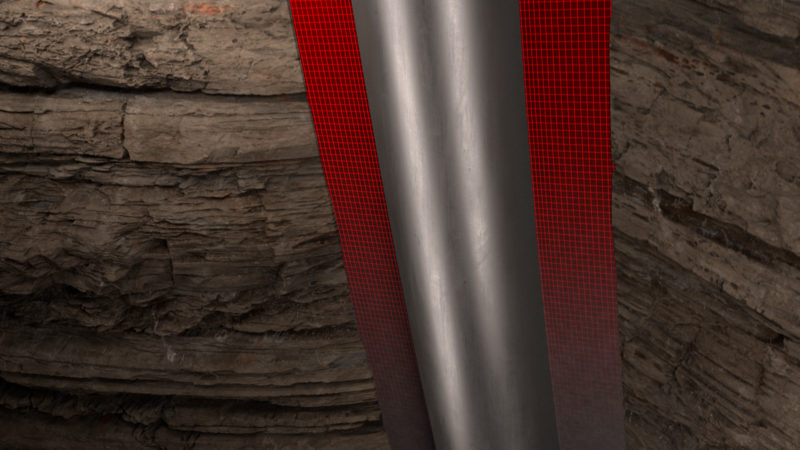

Halliburton proposed deployment of the IsoBond™ cement system to deliver the required barrier and meet the operator’s zonal isolation requirements. The IsoBond cement system proactively mitigates potential flow mechanisms, which include annular flow through unset cement, mud channels, and cement permeability. The IsoBond system tightly controls fluid loss to help ensure successful cement placement in challenging formations, while filtrate loss to the nearby formation is minimized. Laboratory results performed with various densities executed in different temperatures show that the IsoBond system provides excellent fluid-loss control in 30 minutes. In addition, its rapid static gel strength helps mitigate the risk of flow through the cement and channeling, which can lead to sustained casing pressure.

Achieved in the intermediate sections

Cement coverage in the production section

Losses during operation

A sonic or ultrasonic log was run for verification to evaluate zonal isolation. In the intermediate section, it is common to experience a rapid fluid-level decrease attributed to losses, which results in the loss of the barrier between Dammam and the surface. Effective equivalent circulating density (ECD) management with optimized IsoBond cement system rheology during field execution helped achieve the required top of cement (TOC) and zonal isolation requirements in the intermediate sections.

In the production section, considering the complexity of the reservoir zones and the operator’s production objectives, the Mishrif and Zubair formations were 100% covered with cement to help ensure hydraulic isolation and implement the well completion strategy.

The use of the IsoBond cement system prevented unwanted fluid flow from the permeable zones, which could have resulted in sustained casing pressure (SCP) or crossflow between the DPZs.

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.