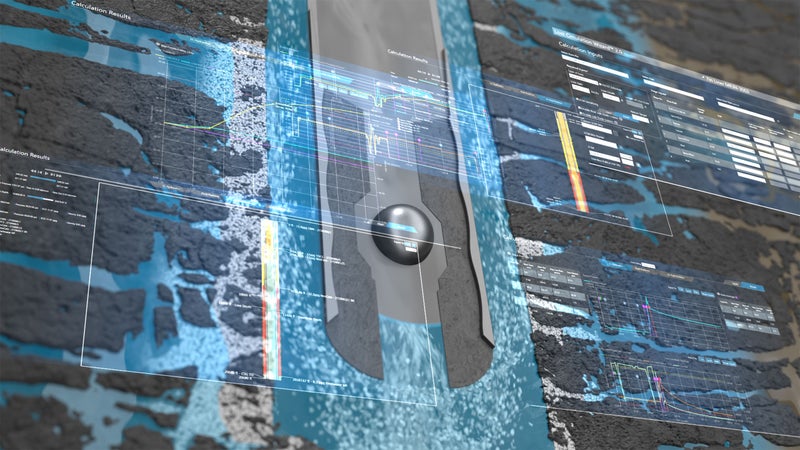

Barrier design and tailoring digital twin enables real-time job monitoring, evaluation, and instantaneous barrier validation

Talk to an expertiCem service enables engineers to make well-informed decisions to tailor the job design, get casing safely to bottom, place cement, and predict cement quality. To design and place effective barriers, iCem service evaluates safe casing placement, lost-circulation material (LCM) strategies using Particle Wizard™ LCM software, and safe/optimal cement placement through 2D hydraulics and 3D displacement efficiency simulations to achieve the required top of cement (TOC).

iCem software models the intermixing of wellbore fluids in annular geometry, considering factors like casing movement, mechanical separation, turbulator centralizers, fluid rheology, standoff, placement rates, and density hierarchy. It predicts fluid displacement efficiency, even in reverse circulation, to optimize shoe track length and cement integrity. The software models fluid concentration over time at all depths, including lost-circulation impacts, for optimum TOC prediction that results in a predictive CBL.

This solution provides predictive capabilities for well cement coverage, which can facilitate compliance with regulatory standards and TOC predictions. iCem service enables rapid “what if” scenario simulations for informed decision-making and better operational predictability.

Operators can remotely access and monitor up to 20 real-time variables from any location, enabling comprehensive job monitoring and data download in a CSV format. The streaming of calculated variables such as downhole ECD and surface pressure allow for the evaluation of design performance against execution. This comparison enables instant TOC assessment based on a real-time pressure match assessment.

The iCem service 2D hydraulics simulator models wellbore hydraulic dynamics throughout the cement application. The simulator matches calculated and real-time surface pressures to ensure downhole hydraulic predictions accurately represent wellbore conditions. This capability makes the modeled TOC predictions highly reliable and crucial for effective zonal isolation and well integrity.

The comparison of real-time and design/planning phase job performance is crucial to evaluate cement operations. Through pressure matching assessments and 2D fluid position modeling post-execution, operators can accurately validate the cement operation. This involves a comparison of real-time data (rate, density, pressure) with preplanned design parameters (open hole size, well geometry, fluid properties, etc.). Alignment of calculated and real-time surface pressures confirms the operation was executed as planned, verifying the modeled TOC and ensuring desired zonal isolation and well integrity.

As an alternate, modeled wellbore conditions are tailored to achieve an optimal match. This helps identify the conditions the wellbore experienced during execution, assess job events, and determine successful zonal isolation.

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Tailored design decisions employed by machine learning to improve the probability of operational success.